Global Metal Cutting Tools Market Overview

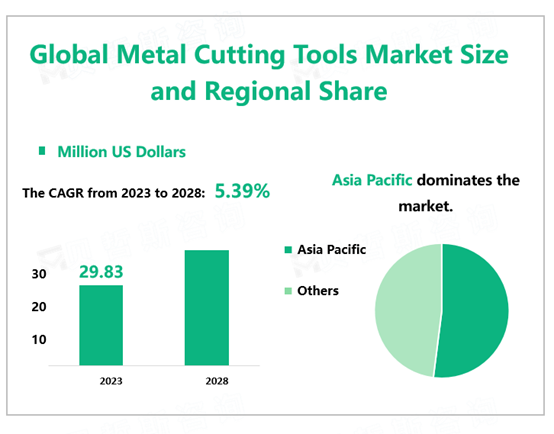

According to Global Market Monitor, the global metal-cutting tool market size will reach $29.83 billion in 2023 with a CAGR of 5.39% from 2023 to 2028.

A metal cutting tool is a machine tool that ensures critical and complex parts can be efficiently and easily manufactured with the highest precision.Metal cutting tools are driven by electric motors and can be used in many cutting processes, including turning, milling, grinding, and boring to complete the required cutting of metal work pieces.

Industry 4.0 is conducive to the Development of the Metal Cutting Tools Industry.

The adoption of Industry 4.0 has had a significant impact on the metal cutting industry, facilitating the development of intelligent cutting tools that can communicate with machines. These tools collect data and make adjustments to optimize performance, and also monitor the cutting process in real-time, and adjust its speed, feed, and other parameters to optimize the cutting process, improve accuracy and efficiency, and reduce waste. In addition, Industry 4.0 enables manufacturers to use data analytics to identify trends, patterns, and anomalies in the production process, which helps manufacturers optimize their products.

Asia Pacific Dominates the Market.

Asia Pacific holds a major market share and is anticipated to remain dominant during the forecast period. This is due to the increasing demand from industries such as construction, automotive, and food & beverage. Rising government initiatives to promote electric vehicles are also expected to push the market progress. For instance, China has restricted investment in new manufacturing plants for traditional vehicles, with the local governments launching a quota for EV production for all manufacturers.

Global Metal Cutting Tools Market SWOT

High initial costs and volatile raw material prices can have a significant impact on the metal-cutting equipment market. As a result, customers are hesitant to invest in new tools, which may slow down the growth of the market, affecting small and medium-sized enterprises. Fluctuations in raw material prices can have a significant impact on the metal-cutting industry. When raw material prices rise, the cost of manufacturing metal tools will also increase, resulting in higher prices for customers, reduced demand for metal-cutting tools, and a slowdown in the market. Fluctuations in raw material prices may make it difficult for manufacturers to plan their production schedules and effectively manage their inventories, causing delayed delivery times, and increased costs for manufacturers, thus further affecting the growth of the market.

|

S |

Rapid growth in construction and manufacturing, increasing demand for cutting tools |

|

Developments in the automotive and aerospace industries |

|

|

The need to improve labor efficiency |

|

|

W |

Global economic fluctuations affecting downstream markets |

|

The fluctuation of raw material prices affects the profit margin of metal-cutting tools |

|

|

O |

Growth in emerging market manufacturing industries such as China, India |

|

Development of materials industry, improvement of manufacturing materials of products |

|

|

T |

Increased industry competition |

|

Rising labor costs |

|

|

Incomplete industry laws and regulations |

We provide more professional and intelligent market reports to complement your business decisions.