Engineering ceramics, also known as silicon nitride ceramics or high-strength ceramics, are made from silicon powder using two processes: reaction sintering and hot pressing. It has almost all the strengths of the modern ceramic family, with generally high strength, extremely excellent wear resistance, and chemical corrosion resistance, and is also a good electrical insulation material.

Overview of Market Development and Analysis of Segmented Markets

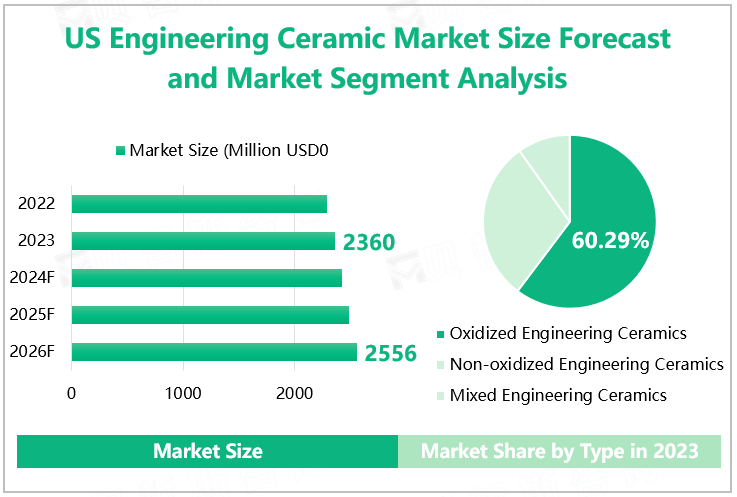

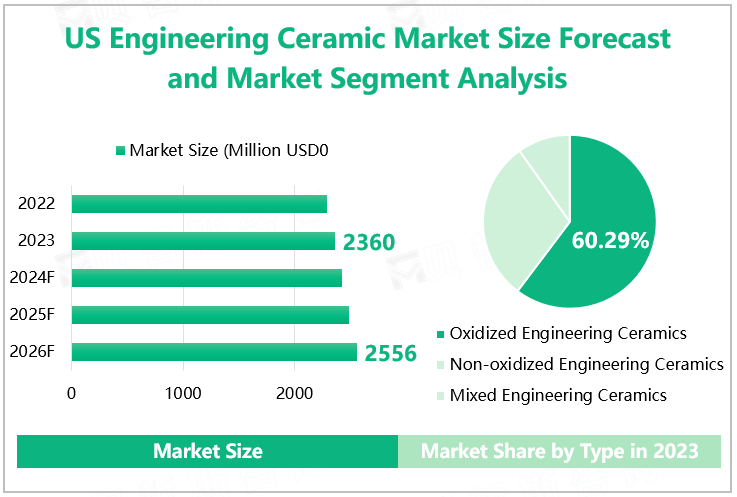

As one of the world's largest economies, the engineering ceramics market in the US is quite large. According to our research data, the market size of US engineering ceramics reached $2360 Million in 2023. In the coming years, with the advancement of technology and the improvement of people's living standards, the application fields of engineering ceramics will further expand, and the market will continue to expand. It is expected that by 2026, the market size of US engineering ceramics will increase to $2556 million.

From the perspective of product types, engineering ceramics can be divided into two categories based on their different uses: structural ceramics and functional ceramics. Structural ceramics have the characteristics of high strength, high hardness, wear resistance, corrosion resistance, etc., and are mainly used in components that withstand mechanical loads, such as bearings, pistons, bearing shells, etc. Common structural ceramics include alumina ceramics, silicon carbide ceramics, silicon nitride ceramics, etc. Functional ceramics have excellent insulation performance, conductivity, and dielectric constant stability, and are mainly used in special functional applications such as electronic devices, sensors, dielectrics, etc. Common functional ceramics include alumina ceramics, zirconia ceramics, cerium-stabilized zirconia ceramics, etc.

According to different chemical properties, engineering ceramics can be divided into three categories: oxidized engineering ceramics, non-oxidized engineering ceramics, and mixed engineering ceramics. Among them, oxide engineering ceramics dominate the market. According to our data, the size of the US oxide engineering ceramic sub-market in 2023 was $1423 million, with a market share of 60.29%.

US Engineering Ceramic Market Size Forecast and Market Segment Analysis

Source: www.globalmarketmonitor.com

Analysis of Market Competition Pattern

The application of engineering ceramics in the US market is mainly concentrated in high-end manufacturing, aerospace, medical, construction, and other fields. In terms of region, the engineering ceramics market in the US is mainly concentrated in economically developed regions such as California, New York, and Texas. The manufacturing, aerospace, medical, and other industries in these regions are developed, and there is a high demand for engineering ceramics.

From the perspective of market competition, the concentration of the US engineering ceramics market is relatively high. Data shows that in 2023, the total sales value of engineering ceramics by the top 3 companies in the industry was $1139 million, with a total sales share of 48.24%. The top 3 enterprises accounted for nearly half of the market. The top 3 companies were Coring, CoorsTek, and NGK Insulators. In 2023, these three companies accounted for 21.40%, 17.95%, and 8.89% of their engineering ceramic sales in the global market, respectively.