Thermoplastic Elastomer (TPE) is an environmentally

friendly low-carbon composite material that combines the characteristics of

rubber (such as high elasticity, compression permanent deformation, etc.) with

the processing characteristics of plastic (simple process). At normal operating

temperatures, one phase is a fluid (causing the temperature to be higher than

its glass transition temperature), the other phase is a solid (causing the

temperature to be lower than or equal to its glass transition temperature), and

there is interaction between these two phases.

Thermoplastic elastomers (TPE) can be formed by

secondary injection molding, coated, and bonded with matrix materials such as

PP, PE, PC, PS, ABS, etc., or can be formed separately.

Introduction to Subdivision Types

|

TPR

|

This

is a material modified by blending SEBS and SBS as substrates. In China, SEBS

as the substrate is usually referred to as TPE, while SBS as the substrate is

referred to as TPR. Although called differently in different regions, they

belong to the same material and are all thermoplastic styrene elastomers.

|

|

TPU

|

This

is a highly transparent elastomer with good weather resistance and

high-energy radiation resistance.

|

|

TPO

|

Composed

of EPDM and PP, it can be used for direct injection molding and flexible

packaging materials.

|

|

TPEE

|

This

is a block copolymer containing both polyester hard segments and polyether

soft segments.

|

Source: www.globalmarketmonitor.com

Market Development Overview and Analysis of Market Development in Major Countries

TPE is environmentally friendly and non-toxic, with a wide range of hardness and excellent coloring, weather resistance, fatigue resistance, and temperature resistance. Its processing performance is superior and does not require vulcanization. Therefore, it is widely used in many fields such as automobiles, electronics, medicine, construction, and consumer goods, and its market size is steadily increasing year by year.

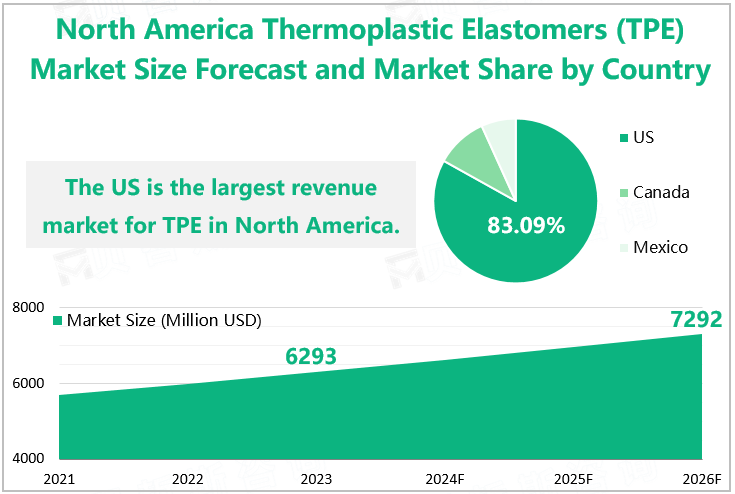

According to our research data, the total consumption of TPE in North America in 2023 was 1827.5k tons, with a market size of $6293 million. In the coming years, with the continuous development of various downstream fields, the demand for TPE will continue to rise. It is expected that by 2026, the total consumption of TPE in North America may increase to 2147.7k tons, and the market size is expected to increase to $7292 million. Meanwhile, with the increasing awareness of environmental protection and the popularization of sustainable development concepts, more and more downstream industries are paying attention to the environmental performance and recyclability of products. Therefore, the future market for thermoplastic elastomers will place greater emphasis on environmental protection and sustainable development.

From the perspective of market development in major countries, the US is the largest consumer market for TPE in North America. The data shows that in 2023, the consumption of TPE in the US was 1506.0ktons, accounting for 82.47% of the total consumption in North America, with a market size of $5229 million and a market share of 83.09%; The market share of Canada and Mexico was 10.13% and 6.78%, respectively.

North America Thermoplastic Elastomers (TPE) Market Size Forecast and Market Share by Country

Source: www.globalmarketmonitor.com