Slurry pump is a widely used equipment in

industries such as mines, power plants, water transportation, railways, and

construction. It is mainly used to transport corrosive, abrasive, viscous,

oily, and fibrous media containing solid particles, as well as corrosive liquids.

Introduction to Subdivision Types

|

Classified

by working principle

|

-

Positive displacement slurry pump:This

type of pump generates pressure through the reciprocating motion of a piston

or plunger to discharge mud. Its characteristic is stable flow rate, but

significant pressure fluctuations.

-

Rotary slurry pump:This

type of pump transports mud through the rotation of the impeller and has the

characteristics of a large flow rate and stable pressure. Common rotary slurry

pumps include centrifugal pumps and mixed flow pumps.

|

|

Classified

by structural characteristics

|

-

Single stage single suction slurry pump:This

type of pump only has one impeller, and the inlet and outlet are in the same

straight line. It has a simple structure and is suitable for small flow and

high-head situations.

-

Multi-stage multi-suction slurry pump:This

type of pump has multiple impellers, and each impeller has an independent

inlet and outlet, suitable for high flow and low head situations. In

addition, there is a distinction between vertical slurry pumps and horizontal

slurry pumps, mainly based on the installation method of the pumps.

|

|

Classified

by purpose

|

-

Engineering slurry

pump:mainly used for mud transportation and drainage

in construction, bridge, tunnel, and other engineering projects.

-

Slurry pump for

oil drilling:used for circulating mud

during the oil drilling process to maintain wellbore stability. This type of

pump has the characteristics of high pressure and a large flow rate.

-

Slurry pump for mining:used for drainage and mud transportation in

mines, requiring high wear resistance and reliability.

|

Source: www.globalmarketmonitor.com

Overview of Market Development and Analysis of Segmented Markets

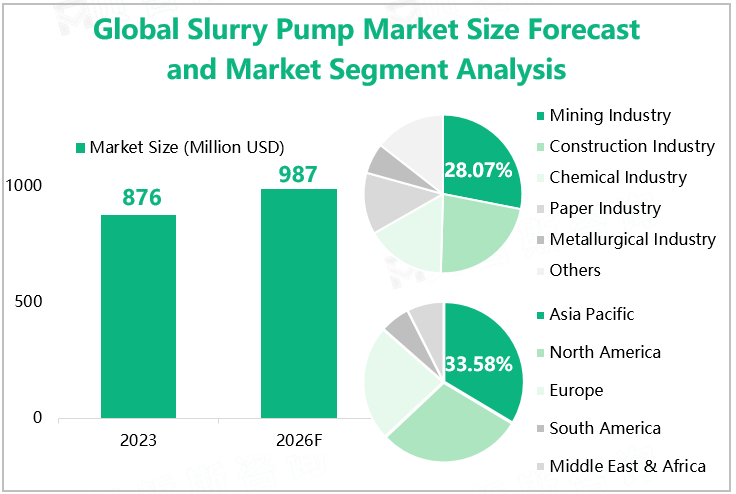

Slurry pumps are essential key equipment in industries such as oil and natural gas, and their market demand is closely linked to the development of the global energy industry. In recent years, with the continuous growth of global energy demand and the improvement of mining efficiency brought about by technological progress, the slurry pump market has shown a steady growth trend. According to our research data, the global slurry pump market size in 2023 was $876 million, an increase of 3.84% compared to 2022.

From the perspective of downstream application patterns, the application of slurry pumps involves many fields such as mining, construction, chemistry, papermaking, and metallurgy. Among them, the mining industry is the largest downstream application market, with a market share of 28.07% in 2023.

From a regional distribution perspective, the global slurry pump market is mainly concentrated in North America, Europe, and the Asia Pacific region. Among them, the Asia Pacific region was the largest revenue market, with a market share of 33.58% in 2023; Due to the development and utilization of unconventional oil and gas resources such as shale gas, the demand for slurry pumps in North America is particularly strong, making it the second largest revenue market with a market share of 29.41% in 2023.

Global Slurry Pump Market Size Forecast and Market Segment Analysis

Source: www.globalmarketmonitor.com

Market Outlook Forecast

In the coming years, with the continuous growth of global energy demand and the further development and utilization of unconventional oil and gas resources, the market demand for slurry pumps will further increase. Meanwhile, with the continuous advancement of technology, new slurry pumps will achieve greater breakthroughs in performance, efficiency, reliability, and other aspects to meet the growing market demand. This will further promote the development of the slurry pump market. It is expected that by 2026, the global slurry pump market size will increase to $987 million.