HDPE is a plastic material. According to different

processing methods, HDPE can be made into various types of containers,

including blow molding containers and injection molding containers. Both blow

molding and injection molding containers exhibit excellent durability, chemical

resistance, and environmental friendliness, making HDPE materials widely used

in people's daily lives.

Introduction to Subdivision Types

|

HDPE

Blow Molding Container

|

Blow

molding is a process of heating and softening plastic, and then blowing it

into shape through air pressure. HDPE blow molding containers have good

durability, sealing, and chemical stability, and are commonly used for

packaging liquid products such as detergents, shampoo, milk, fruit juice,

etc.

|

|

HDPE

Injection Molding Container

|

Injection

molding is a process of heating and melting plastic, and then injecting it

into a mold under high pressure for molding. HDPE injection molded containers

have precise dimensions, good appearance, and high mechanical strength, and

are commonly used for packaging solid or semi-solid products, such as

pharmaceuticals, cosmetics, food, etc.

|

|

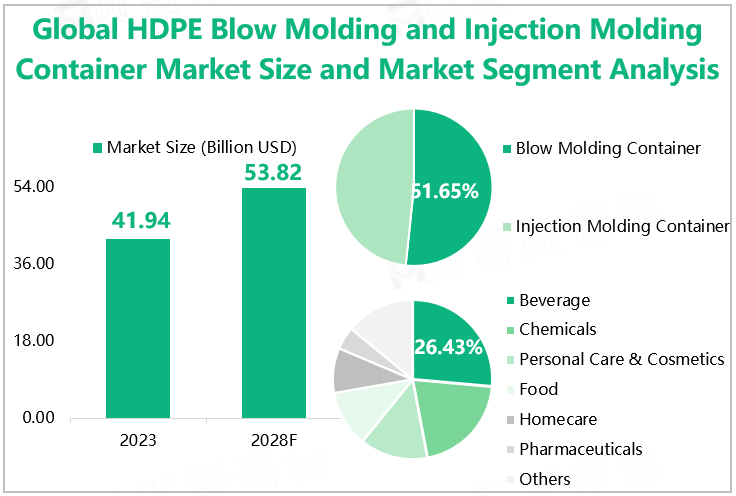

HDPE blow molding containers and HDPE injection molded containers hold

equally important positions in the market, with market shares of 48.35% and

51.65% respectively in 2023.

|

Source: www.globalmarketmonitor.com

Overview of Market Development

In recent years, the global market size of HDPE blow molding and injection molding containers has been continuously expanding. This is mainly due to the following aspects: firstly, the rapid development of the global packaging industry has provided broad space for the HDPE blow molding and injection molding container market; Secondly, the increasing awareness of environmental protection among people has led to the popularity of reusable HDPE containers; Thirdly, HDPE material itself has good durability, moisture resistance, and impact resistance, making it suitable for various environments and usage scenarios.

According to our research data, the global market size of HDPE blow molding and injection molded containers reached $41.943 billion in 2023, an increase of 5.13% compared to 2022. It is expected that the market size will continue to increase to $53.82 billion by 2028.

Analysis of Downstream Application Pattern

From the perspective of downstream applications, the application of HDPE blow molding and injection molding containers involves many industries and fields such as food, beverage, chemicals, personal care, cosmetics, pharmaceuticals, etc. Among them, the beverage industry was the largest downstream application market, with a market share of 26.43% in 2023.

Global HDPE Blow Molding and Injection Molding Container Market Size and Market Segment Analysis

Source: www.globalmarketmonitor.com

Development Trend Analysis

Environmental trend: With the increasing global environmental awareness, the future HDPE blow molding and injection molding container market will pay more attention to environmental protection and sustainable development. Enterprises and governments will increase their research and promotion efforts on environmentally friendly HDPE containers, promoting the market in a more green and environmentally friendly direction.

Technological innovation: Technological innovation is an important factor in promoting the development of HDPE blow molding and injection molding container markets. In the future, with the continuous emergence of new materials, processes, and technologies, the performance of HDPE containers will be further improved, and their application fields will also be more extensive.

Personalized demand: With the increasing demand for personalized products from consumers, the HDPE blow molding and injection molding container market will also usher in the demand for personalized customization. Enterprises need to continuously improve their design capabilities and production flexibility to meet the personalized needs of consumers.