Chemical vapor deposition (CVD) of SiC, abbreviated as CVD SiC, is a type of SiC material prepared by the chemical vapor deposition (CVD) method. CVD is a process that utilizes gaseous or vapor substances to react at gas or gas-solid interfaces to generate solid deposits. During the preparation process of CVD SiC, the reaction gas diffuses towards the substrate surface, adsorbs onto the substrate surface, and undergoes a chemical reaction on the substrate surface to form solid deposits and produce gas-phase byproducts that detach from the substrate surface.

Overview of Market Development

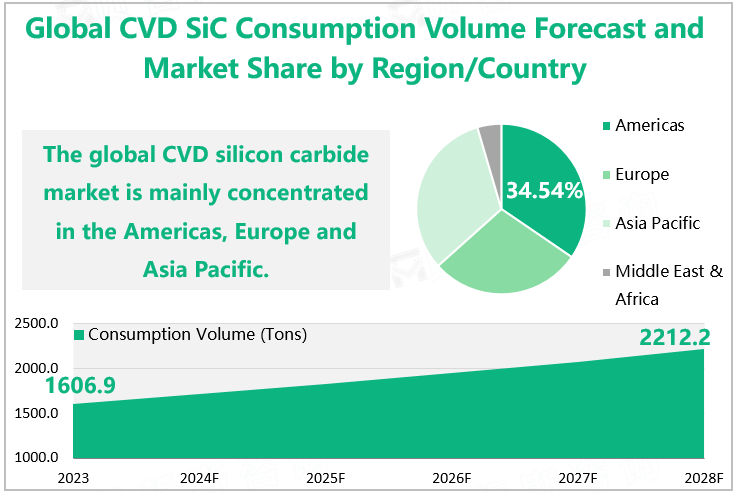

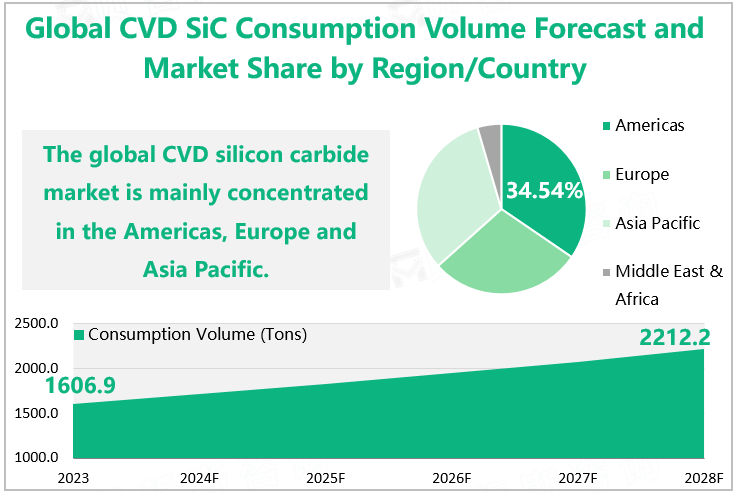

CVD SiC is a unique material that holds an important position in the semiconductor industry due to its excellent thermal, electrical, and chemical properties. In recent years, with the continuous progress of semiconductor technology, the demand for CVD SiC materials has also been steadily increasing. According to our research data, the global consumption volume of CVD SiC in 2023 was 1606.9 tons, an increase of 6.39% compared to 2022, and the market size was $200 million, an increase of 5.26% compared to 2022. It is expected that by 2028, the global consumption volume of CVD SiC will increase to 2212.2 tons.

Market Analysis of Major Regions

From a regional perspective, the global CVD SiC market is mainly concentrated in the Americas, Europe, and the Asia Pacific region. Among them, the Americas is the largest consumer market. The data shows that the consumption volume of CVD SiC in the Americas in 2023 was 5.55 tons, accounting for 34.54% of the global total consumption volume.

Global CVD SiC Consumption Volume Forecast and Market Share by Region/Country

Source: www.globalmarketmonitor.com

Segmented Market Analysis

From the perspective of product types, CVD SiC can usually be classified into high resistivity level, medium resistivity level, and low resistivity level based on the different resistivity levels. Among them, high resistivity grade and low resistivity grade CVD SiC dominate the market, with consumption volume proportions of 39.54% and 49.36% in 2023, respectively.

From downstream applications, CVD SiC is mainly used in LED wafer carriers and covers, plasma etching components, rapid heat treatment components, bases, and virtual wafers. Among them, the field of plasma etching components is its downstream application market. The data shows that in 2023, the consumption volume of CVD SiC in the field of plasma etched components was 561.2 tons, accounting for 34.92% of the consumption volume.

Global CVD SiC Consumption Volume and Proportion by Type and Application in

2023

|

|

Consumption Volume (Tons)

|

Proportion

|

|

Segmented by Type

|

|

High Resistivity Grade

|

635.4

|

39.54%

|

|

Middle Resistivity Grade

|

178.3

|

11.10%

|

|

Low Resistivity Grade

|

793.2

|

49.36%

|

|

Segmented by Application

|

|

Rapid Thermal Process Components

|

286.5

|

17.83%

|

|

Plasma Etch Components

|

561.2

|

34.92%

|

|

Susceptors & Dummy Wafer

|

340.7

|

21.20%

|

|

LED Wafer Carriers & Cover Plates

|

260.2

|

16.19%

|

|

Others

|

158.2

|

9.85%

|

Source: www.globalmarketmonitor.com

For more industry information, please refer to our latest released "2023 Global CVD SiC Market Analysis Report, Key Competitors, Market Effect Factors, Growth, And Forecast".