Global Electro Galvanizing Market Overview

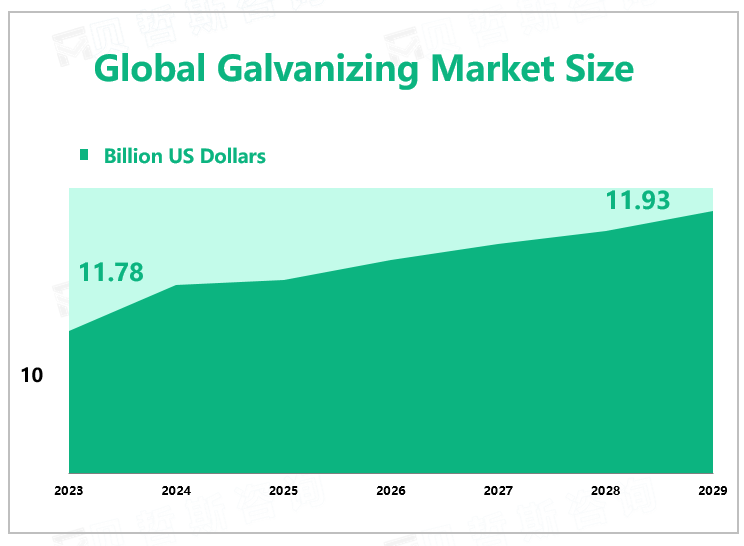

According to Global Market Monitor, the global electro-galvanizing market size will reach $11.78 billion in 2024 and is expected to grow to $11.93 billion by 2029.Electro galvanizing is a process of bonding a layer of zinc to steel to prevent corrosion. This process involves electroplating, running current through a brine/zinc solution with a zinc anode and a steel conductor.、

Market Drivers and Restraints

Electroplated products have a short life due to the thin zinc layer. In the short term, if the pickling is insufficient, the air is humid, and dezincification and oxidation will occur in a few weeks.

A completely different process from hot dip galvanizing, in which a zinc coating is applied to the steel, wherein the anode is zinc, the cathode is steel, and the electrolyte is zinc sulfate. In other words, plating instead of zinc immersion. This process consumes a lot of electricity and increases the cost of electroplating, so the price of Electro-galvanizing is relatively high.

Most high-end factories still use electro-galvanized products. In industries other than ordinary white goods such as LCD TVs, printers, copiers, and other high-end microelectronics, the use of fingerprint-resistant electro-galvanized steel sheets is still growing. Due to the excellent corrosion resistance and surface quality of electro-galvanized steel sheets, high-grade cars have been using electro-galvanized steel sheets. In addition, the anti-fingerprint-treated electro-galvanized steel sheets have the characteristics of anti-fouling on fingerprints and oil stains, making them electroplated a boutique of zinc products. Energy and labor costs have risen, consumers have strong purchasing power, and demand for and demand for home appliances has continuously increased, thus promoting the development of the electroplating zinc market.

Regional Market Status

In North America, the U.S. is an important consumer of electro-galvanizing. The region has been witnessing steady growth due to its strict environmental regulations. Electro galvanizing in Europe is mainly concentrated on the production of automobiles, electronic goods, wire fencing posts for agriculture, doors, and windows as well as hospital equipment. Germany is one of its fastest-growing regions. This region also boasts strong environmental laws which have led to reduced production capacity across different countries that will drive imports into this area in coming years. The Asian nations have witnessed considerable growth led by increasing industrialization which has resulted in higher consumption levels across different sectors including construction and automotive. This will be achieved through greater production capacities combined with investments in new technologies to improve quality. The Middle Eastern countries, including Saudi Arabia and Iran, are witnessing an increase in demand due to industrialization which has been driving growth across different sectors like construction as well as automotive.

|

By Type |

Alkaline Electrolytes |

|

Acidic Electrolytes |

|

|

The alkaline electrolytes segment contributes the largest market share. |

|

|

By Application |

Automotive Industry |

|

Home Appliance |

|

|

Electronic Product |

|

|

Construction Industry |

|

|

Light Industry |

|

|

Others |

|

|

The home appliance segment occupies the biggest share. |

We provide more professional and intelligent market reports to complement your business decisions.