Nordic Laser Cutting Machines Market Overview

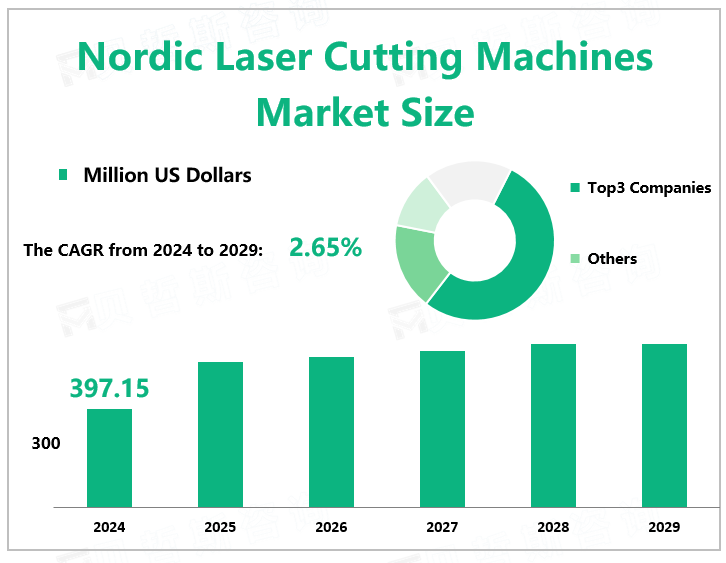

According to Global Market Monitor, the Nordic laser cutting machines market size will reach $397.15 million in 2024 with a CAGR of 2.65% from 2024 to 2029.

Laser cutting is a technology that uses a laser to cut materials. Laser cutting works by directing the output of a high-power laser most commonly through optics. Laser optics and CNC (computer numerical control) direct the material or the laser beam generated. The laser cutting machines initially cast a laser beam on the piece's surface, melt it, and finally evaporate the particular area of the piece using the energy released by the laser.

Fierce Market Competition with Homogeneous Companies

There is no major performance difference between most industry leaders' products, and product homogeneity is obvious. For enterprises, the development of technology requires higher and higher laser cutting machines, speed, accuracy, and maintenance costs. At the same time, laser cutting is also moving towards high-power and automated processing. These increasing market requirements are also challenging for enterprises.

North American and European companies have mastered core technologies, so they have a technological advantage for a long time. However, with the advancement of research and development and product updates in emerging countries, their products have cost advantages under the same performance. In other words, the invasion of foreign brands poses a greater threat to its market share.

Expansion of Applications and Market Growth

The proportion of laser cutting machines is increasing in the Nordic laser application technology. With the advancement of technology and cost, the market for laser-cutting machines in North Europe is also growing. Due to their high speed, high quality, and small heat-affected zone, laser cutting machines are used in sheet metal processing, automobile manufacturing, aviation, kitchen, and kitchenware industries.

The growth of the laser cutting machines market is driven by the rising adoption of industry 4.0 technologies such as automation, data analytics, and the Internet of Things (IoT) are assisting in maximizing the efficiency of laser cutting machinery due to the real-time information exchange that enables optimum output by enabling operators to monitor and manage their production processes. Manufacturers aim to improve operating cost-efficiency, decrease downtime, and enhance production.

Key Companies Introduction

Trumpf is a world leader in industrial machine tools, laser technology, and electronics. Factories are located all over the world.TRUMPF was founded in 1923 as a series of mechanical workshops and has since developed into one of the world's leading companies for machine tools, laser technology, and electronics for industrial applications. In the 2022/23 fiscal year, the company, with its 18,352 employees, generated sales revenues of 5,364.5 million euros. With more than 70 subsidiaries, the group is represented in nearly every European country, in North and South America, and Asia. Production facilities are located in Germany, France, Great Britain, Italy, Austria and Switzerland, Poland, the Czech Republic, USA, Mexico and China.

|

Company Name |

Trumpf |

|

Website |

www.trumpf.com |

|

Established Time |

1923 |

|

Plants Distribution |

Worldwide |

|

Sales Region |

Worldwide |

|

Market Position or History |

Industry leader |

|

Competitors |

Bystronic, Prima Power |

|

Product Introduction |

2D laser cutting machines TruLaser Serie 1000 TruLaser Serie 3000 TruLaser Serie 5000 TruLaser Center 7030 TruLaser 8000 Coil Edition 3D laser cutting machines TruLaser Cell 3000 TruLaser Cell 5030 TruLaser Cell 5030 Hotforming Edition TruLaser Cell 7040 TruLaser Cell 8030 |

We provide more professional and intelligent market reports to complement your business decisions.