Global Inverter Welding Machine Market Overview

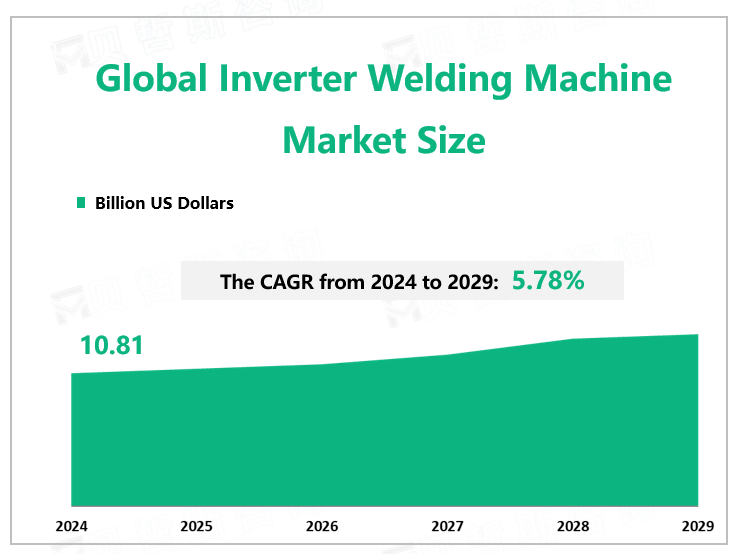

According to Global Market Monitor, the global inverter welding machine market size will reach $10.81 billion in 2024 with a CAGR of 5.78% from 2024 to 2029.

Automatic Welding Equipment is Favored in Various Industries.

Automated welding machines are being used on a large scale in all walks of life to speed up the production process and produce high-quality products. Manufacturing units in various industries are installing automated welding assembly lines to achieve maximum speed during the welding process, resulting in better products. To achieve automation on a large scale, manufacturers offer pre-configured robotic welding units. This can reduce over-welding, improve quality, and speed up overall production. Various industries, including automobiles, buildings, and buildings, are becoming highly automated. Welding equipment manufacturers are also conducting extensive research to develop welding techniques and equipment to help weld new materials used in various industries.

Arc welding is the most preferred technique for the manufacture of pipes, offshore structures, and other process equipment. Arc welding technology is widely used in chassis components because it is easy to connect continuously and provides high-strength and rigidity joints. Advanced arc welding technology has also been introduced to increase productivity and efficiency. The increasing trend of vehicle body weight reduction has also driven the demand for advanced arc welding technology. However, arc welding still has great applications in joining thick plates to build large steel structures. At the same time, advanced arc welding technology is increasing productivity and efficiency compared to conventional arc welding techniques.

Inverter Welding Machine Application Field Analysis

Inverter welding machines are widely used in the high-tech industry to weld thin and delicate materials, helping to produce a stable, low thermal output arc, which is ideal for welding thin materials without causing any damage. Heavy industry is one of the main application areas of inverter welders for welding large and heavy components together, common applications include the construction of ships, pipelines, Bridges, and other structures. High-power inverters provide stable welding even under harsh environmental conditions and are also able to handle thicker metals with ease, making them the first choice for heavy industry applications. The application of inverter welding machines in the light industry mainly includes the production of small parts and components such as screws, nuts, washers, brackets, frames, and housings, and can also be used for welding sheets or pipes. Inverter welders provide high-quality welds with low deformation and good bead appearance.

|

By Type |

MMA Inverter Welder |

|

MIG/MAG Inverter welder |

|

|

TIG Inverter welder |

|

|

The MIG/MAG Inverter welder segment contributes the largest market share. |

|

|

By Application |

High-Tech Industry (Nuclear Energy) |

|

Heavy Industry (Wind Tower Fabrication) |

|

|

Light Industry (Farm & Ranch) |

|

|

The high-tech industry (Nuclear Energy) segment occupied the biggest share. |

We provide more professional and intelligent market reports to complement your business decisions.