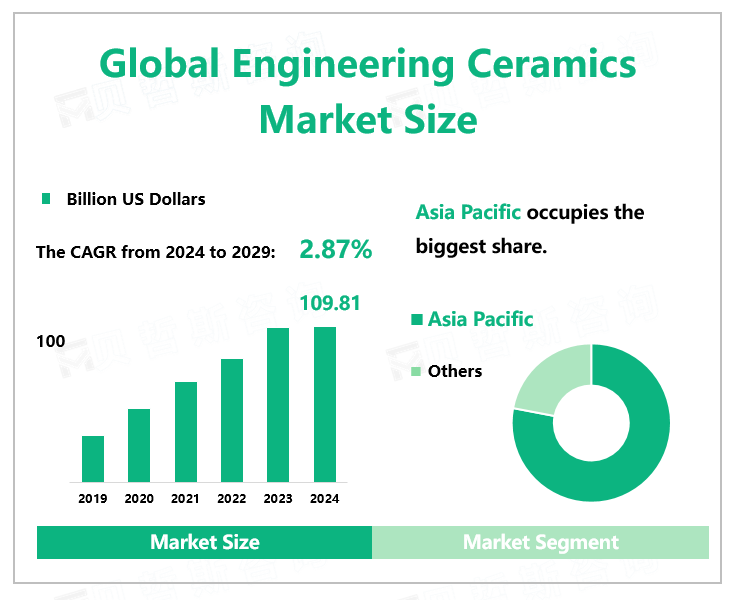

According to Global Market Monitor, the global engineering ceramics market will reach $109.81 billion in 2024 with a CAGR of 2.87% from 2024 to 2029.Engineering ceramics have high hardness, strength, high-temperature resistance (refractory), abrasion resistance, corrosion resistance, excellent performance such as acid and alkali, oxidation resistance, insulation, non-magnetic, and good chemical stability.

Application Fields and Regional Markets

The properties of engineered ceramics such as low thermal expansion, robustness, and high-temperature stability are becoming increasingly popular in various end-use applications such as electrical and electronics, automotive, etc., positively influencing the market growth. With innovative technology and superior functional characteristics, it is expected to replace traditional materials to a large extent.

Due to the growing usage in the electronics, semiconductor, and automotive industries, the Asia Pacific region dominates the global engineered ceramics market. The development of the automotive and medical industries in the emerging economies of the Asia-Pacific region is expected to drive the growth of the market. North America is the second-largest engineered ceramics market and increasing opportunities, supported by a growing industrial sector, are driving demand in the region. In the United States, the use of products in the environmental and medical fields is growing significantly, and the northeast of the United States is high-tech industry-intensive, with excellent talents, a good economic foundation, and research and development capabilities, and there is a certain demand.

Market Drivers

Ceramic materials have the characteristics of wear resistance, corrosion resistance, high-temperature resistance, oxidation resistance, thermal shock resistance, and low specific gravity which are difficult to compare with general metal materials. It can withstand the harsh working environment that metal or polymer materials are difficult to handle and have broad application prospects. It has become a key basic material supporting the 21st-century pillar industry after metal materials and polymer materials and has become one of the most active research fields. Today, all countries in the world attach great importance to its research and development. Electronics for space and other harsh environments. These could all be made possible thanks to a new ceramic welding technology. The process works in ambient conditions and uses less than 50 watts of laser power, making it more practical than current ceramic welding methods that require heating the parts in a furnace.

Market Limitations

The scope of research in ceramic engineering includes the purification of raw materials, the research and Sales of the required chemical components, and the study of the structure, composition, and properties of the products. At the same time, the structure is subtle, the composition of the composite and the integration of structural functions are the development direction of ceramic engineering research. If participants expect to have an advantage in the international market, a large amount of R&D spending is essential. Engineering ceramics generally have high shear stress resistance, extremely low tensile strength, large elastic modulus, and high brittleness, which make the processing cost high, the efficiency low, and the processing quality not ideal. At the same time, the cost of processing equipment also limits sales.

|

Drivers |

Continuous research and innovation |

|

More and more applications |

|

|

Development of high-tech industry and outstanding talents |

|

|

Limitations |

High Sales cost |

|

High-tech research and development costs |

We provide more professional and intelligent market reports to complement your business decisions.