Electric vehicle (EV) die-casting components are components manufactured through die-casting technology in electric vehicles. Die-casting is a metal casting process that operates similarly to injection molding, applying high pressure to melted metal and injecting it into a mold to cast the desired shape of the component. This process has the characteristics of high efficiency and high quality, and is widely used in fields such as automobiles, aviation, and machinery.

Overview of Market Development

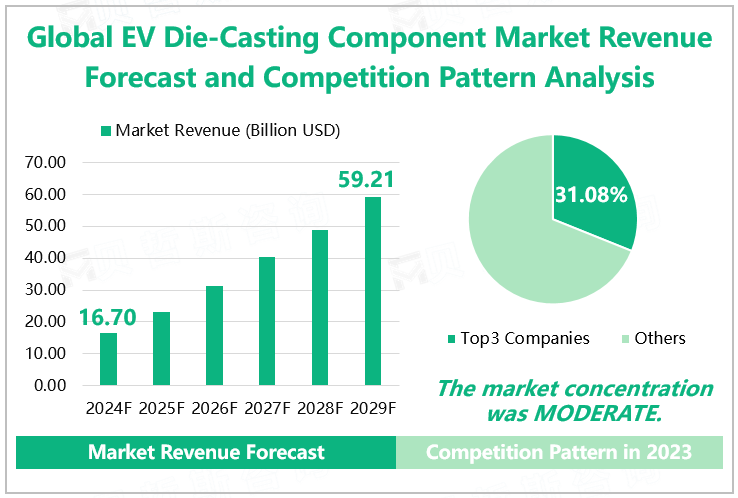

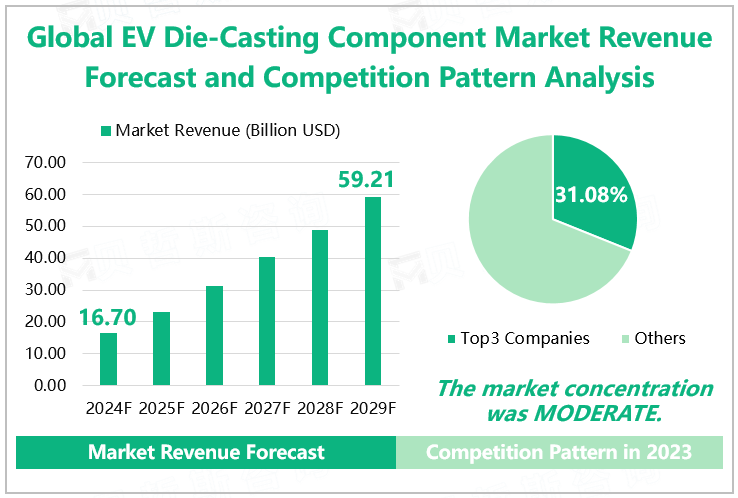

As a key component of electric vehicles, the performance and quality of die-casting components have a significant impact on the overall performance of electric vehicles. In recent years, with the rapid growth of the global electric vehicle market, the demand for EV die-casting components has continued to expand. According to our research data, the global EV die-casting market revenue is expected to reach $16.70 billion in 2024, an increase of 56.27% compared to 2023.

In the future, it is expected that the market will continue to maintain a rapid growth trend. By 2029, the global EV die-casting market revenue is expected to continue to increase to $59.21 billion. The CAGR for 2024-2029 is estimated to be 28.81%. In addition, with the continuous advancement of new energy vehicle technology and the increasing demand for automotive performance from consumers, it is expected that high-performance, lightweight, and environmentally friendly die-casting components will become the mainstream in the market.

Analysis of Market Competition Pattern

From the perspective of market competition, the concentration of the global EV die-casting component market is moderate. The data shows that the total output value of EV die-casting components for the top 3 enterprises in 2023 was $3.32 billion, with a total output value share of 31.08%. The top three companies were RYOBI, Hitachi Metals, and Ningbo Xusheng Auto Technology Co. In 2023, these three companies accounted for 11.08%, 10.60%, and 9.40% of the global market share for EV die-casting products, respectively.

Global EV Die-casting Component Market Revenue Forecast and Competition Pattern Analysis

Source: www.globalmarketmonitor.com

Segmented Market Analysis

From the perspective of product types, EV die-casting components can be classified according to materials, such as aluminum alloy die-casting components, steel die-casting components, etc. Aluminum alloy die-casting components have been widely used in electric vehicles due to their lightweight, strong corrosion resistance, and compact structure.

According to different die-casting processes, EV die-casting components can be divided into high-pressure die-casting (HPDC) components, gravity die-casting (GDC) components, and low-pressure die-casting (LPDC) components. Among them, HPDC components dominate the market, and the market share is expected to reach 72.52% in 2024.

From the perspective of downstream applications, the application of electric vehicle die-casting involves the fields of passenger vehicles and commercial vehicles. Among them, the passenger vehicle sector holds the highest market share in the downstream market, estimated at 77.71% in 2024.

Global EV Die-casting Component Segment Market Revenue and Market Share Forecast in 2024

|

|

Market Revenue (Billion USD)

|

Market Share

|

|

Segmented by Type

|

|

HPDC Components

|

12.11

|

72.52%

|

|

GDC Components

|

2.12

|

12.70%

|

|

LPDC Components

|

1.77

|

10.59%

|

|

Others

|

0.70

|

4.18%

|

|

Segmented by Application

|

|

Passenger Vehicles

|

12.97

|

77.71%

|

|

Commercial Vehicles

|

2.23

|

13.35%

|

|

Others

|

1.49

|

8.95%

|

Source: www.globalmarketmonitor.com