Tube mill is an important fine grinding equipment in modern industry, widely used in building materials, metallurgy, mineral processing, power and chemical industries, for grinding cement and other materials. Its main characteristics include high crushing ratio, high production capacity, strong adaptability to materials, and easy replacement of worn parts.

There are various types of tube mills according to different classification standards. According to the ratio of cylinder length to diameter, it can be divided into short grinding, medium long grinding, and long grinding; According to the production method, it can be divided into dry grinding, wet grinding, and drying grinding; According to the transmission method, it can be divided into center transmission grinding and edge transmission grinding. In addition, there are specialized tube mills for pipe processing, such as inlet tube mills, inner and outer cylindrical mills, fully automatic tube mills, and CNC tube mills, which play an important role in the field of pipe processing.

Overview of Market Development

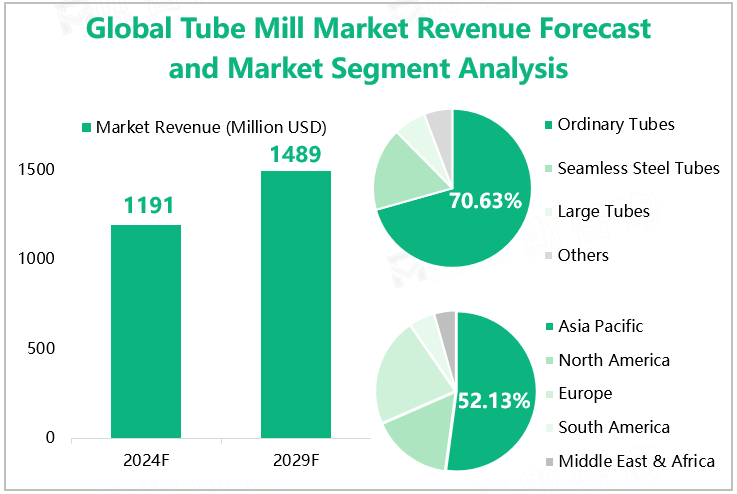

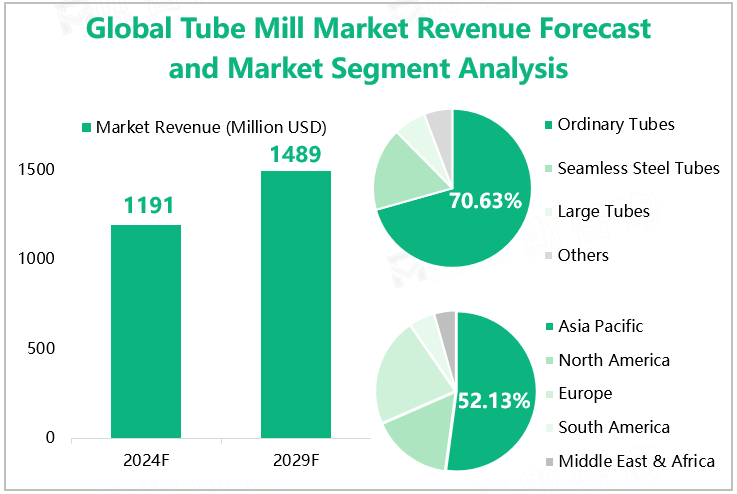

The global tube mill market has shown a steady growth trend in recent years, driven mainly by the continuous promotion of infrastructure construction, manufacturing, and resource development and utilization. According to our research data, the estimated revenue of the global tube mill market in 2024 is $1191 million, an increase of 5.73% compared to 2023, and is expected to continue to increase to $1489 million by 2029. The CAGR for 2024-2029 is estimated to be 4.57%.

From the perspective of development trends, intelligence, automation, and green environmental protection technologies are important development trends in the tube mill market. In the future, tube mill products on the market will pay more attention to energy-saving, emission reduction, high-precision, and high-efficiency processing capabilities.

Segmented Market Analysis

From an application perspective, downstream applications of pipe mills can be subdivided into ordinary tube processing, seamless steel tube processing, and large tube processing based on the different types and characteristics of pipe materials. Among them, ordinary tube processing occupies a dominant position, and the application share is expected to reach 70.63% in 2024.

From a regional perspective, the global tube mill market is dominated by three major regions: North America, Europe, and Asia Pacific. Among them, the Asia Pacific region is the largest revenue market, with an estimated market share of 52.13% in 2024; The European and North American markets are expected to rank second and third with market shares of 21.98% and 16.33%, respectively.

Global Tube Mill Market Revenue Forecast and Market Segment Analysis

Source: www.globalmarketmonitor.com

Analysis of Market Competition Pattern

From the perspective of market competition, the concentration of the global tube mill market is relatively low. According to the data, the total market revenue of tube mills of the top 3 enterprises in 2023 was $303 million, with a total revenue share of 26.81%. The top three companies were SMS Meer, Fives OTO S.p.A., and Zhongtai Group. In 2023, these three companies accounted for 16.57%, 7.25%, and 2.99% of the global market revenue in the tube mill market, respectively.

Tube Mill Market Revenue and Market Share of Top3 Companies in 2023

|

Companies

|

Market Revenue (Million USD)

|

Market Share

|

|

SMS Meer

|

187

|

16.57%

|

|

Fives OTO S.p.A.

|

82

|

7.25%

|

|

Zhongtai Group

|

34

|

2.99%

|

|

Top3 Companies

|

303

|

26.81%

|

Source: www.globalmarketmonitor.com

For more industry information, please refer to our latest released "2023 Global Tube Mill Market Analysis Report, Key Competitors, Market Effect Factors, Growth, And Forecast".