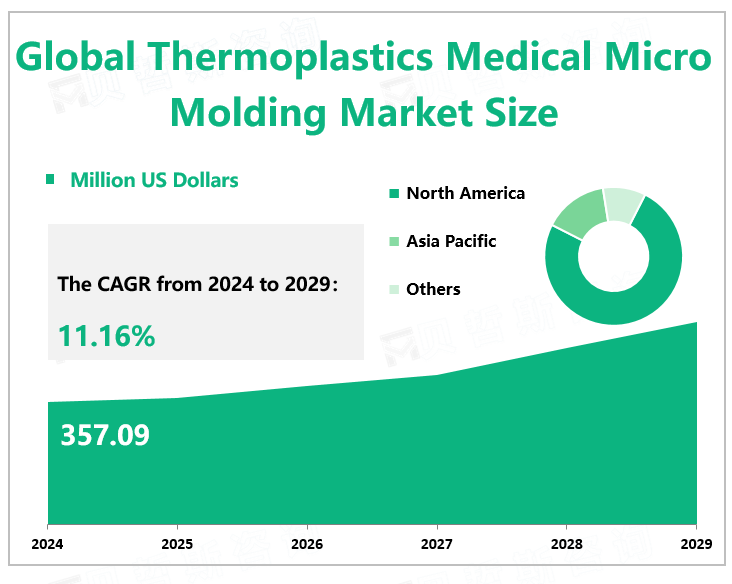

According to Global Market Monitor, the global thermoplastics medical micro molding market size is $357.09 million in 2024 with a CAGR of 11.16% from 2024 to 2029.

Micro molding is a highly specialized manufacturing process that produces tiny, high-precision thermoplastic parts and components with micron tolerances. The process starts in a tooling department where a mold with a cavity in the shape of the desired part is created. Thermoplastic or resin is rapidly injected into the cavity, making the component or part at high speed.

Thermoplastics Material Has Superior Performance.

Polymers have long been considered to have a significant advantage over metals for medical applications. That's because the isotonic saline solution that comprises the body's extracellular fluid is extremely hostile to metals but is not normally associated with the degradation of many synthetic high-molecular-weight polymers. Thermoplastics is a polymer material that becomes flexible and plastic when heated above a certain temperature and hardens into a solid when cooled. Most types of thermoplastic resins are recyclable and can be reheated, reshaped, and reused. Choosing the right medical-grade plastic for a medical device or component is a key decision to make the perfect part. Thermoplastics have become an important material for medical equipment and products due to their unique characteristics, such as strong corrosion resistance, durability, water resistance, lightweight, good flexibility, and low cost. For example, PEEK has strong corrosion resistance, hydrolysis resistance, and chemical resistance, especially inert to body fluids. It can be applied to certain implantable medical devices that relieve the pain of patients, such as gastrointestinal stents and implantable body fluid pumps, thereby eliminating the traditional pain caused by a patient puncture; medical grade polycarbonate is biocompatible Strong, strong corrosion-resistance, not easy to break the advantages, is the first choice for capsule endoscope shell materials. The superior performance of Thermoplastics as a raw material plays an important role in the medical device injection molding manufacturing industry.

High Requirements for the Production Scale and Technical Level

Most of the small and medium-sized Thermoplastics Medical Micro Molding manufacturing companies or a large number of new entrants have a relatively backward infrastructure and lack advanced production and processing equipment. Improving the overall level of the design and manufacturing of special thermoplastics machinery and molds for medical product processing is to accelerate the development of the industry The key is. Quite a lot of products have not formed the output of economic scale, it is not only difficult to form a competitive advantage but also difficult to improve profitability, which will limit the development of the players and even the whole industry. Moreover, with the increasing individual requirements of different customers, manufacturers need to confirm appropriate processing methods and optimize them to match specific applications. The need for such resources includes processing equipment, application testing capabilities, laboratory facilities, and performance data for specific materials.

|

Company Name |

SMC |

|

Website |

www.smcltd.com |

|

Established Time |

1988 |

|

Plants Distribution |

United States |

|

Sales Region |

Worldwide |

|

Business Overview |

SMC Ltd. provides global contract manufacturing solutions for single-use devices for the pharmaceutical, medical, and diagnostics industries. |

We provide more professional and intelligent market reports to complement your business decisions.