Global Polyvinylidene Fluoride Market Overview

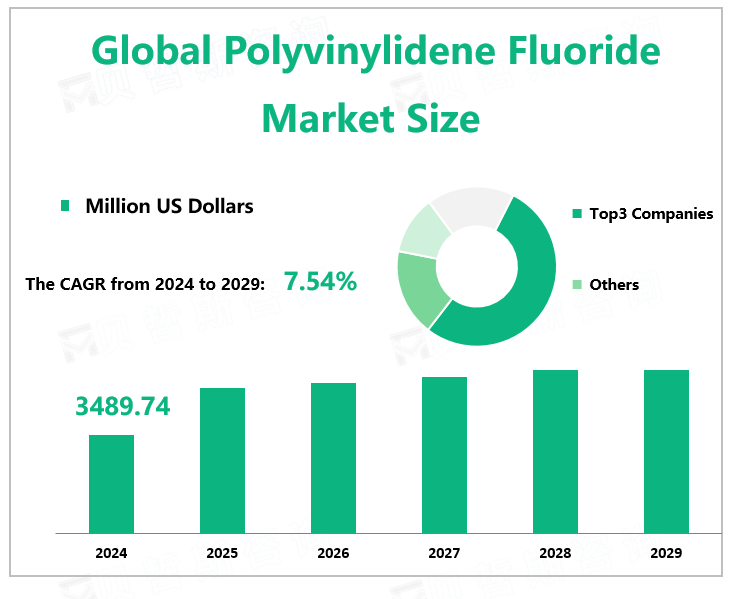

According to Global Market Monitor, the global polyvinylidene fluoride market size will reach $3489.74 million in 2024 with a CAGR of 7.54% from 2024 to 2029.

Polyvinylidene fluoride has outstanding chemical resistance, wear resistance, good UV stability, tensile strength, and high wear resistance. Easy to form, commonly injected, and easily welded, PVDF produces individual polymer sheets and films for the manufacture of a variety of applications, such as major electrical and electronics, branded pipes and pipes, photovoltaic films, defense equipment, and lithium-ion batteries, among other separate applications.

High Performance of the Product and the Extensive Downstream Applications

Owing to properties such as membrane forming, high thermal stability, and good chemical resistance, PVDF has a wide range of applications. It is widely used as metallic coatings in various chemical processing industries for various applications such as heat exchangers, filters, membranes, and pumps. Traditional lining or coating products' poor adhesion of thermoplastics to a metal substrate and lack of consistency in coating applications can affect the service life of metal products. PVDF offers high performance in harsh and wide variety of chemicals. Additionally, it offers superior thermal resistance, corrosion barrier, and abrasion- and chemical resistance. These factors are anticipated to significantly boost the demand for PVDF during the forecast period. PVDF is used as a solvent dispersion coating for architectural applications and shows high solvency in ester and ketone solvents. PVDF possesses crystalline and amorphous phases in its structure due to which PVDF coatings offer superior properties, such as high flexibility and solvent resistance. Rising demand for PVDF in the building & construction industry due to its characteristic features such as high abrasion resistance, high chemical resistance, wear resistance, thermal resistance, UV resistance, and anti-skid. These factors are projected to boost the market during the forecast period.

In addition to that, increasing applications of PVDF in the metal preparation industry to provide corrosion resistance, in the pulp & paper industry to provide resistance against bleaching agents, in the mining industry to provide abrasion resistance, in the food & beverage industry to provide resistance to acidic foods and steam cleaning, in nuclear waste processing to provide high thermal stability, etc., is expected to drive the polyvinylidene fluoride market during the forecast period. Furthermore, PVDF is also used in water treatment plants, ventilation plants, steel-pickling plants, and exhaust-air cleaning plants. Therefore, increasing the aforementioned applications is likely to augment the polyvinylidene fluoride market growth over the forecast period.

Market Competition

Arkema is one of the major players operating in the polyvinylidene fluoride market, holding a share of 31.31% in 2022.Arkema SA engages in the manufacturing and supply of chemical products. The high-performance materials segment includes the technical polymers, filtration and adsorption, and organic peroxides business units and provides solutions with high revenue added, used in varied sectors such as transportation, oil extraction, renewable energies, consumer goods, electronics, construction, coatings, and water treatment.

|

Company Name |

Arkema |

|

Website |

www.arkema.com |

|

Established Time |

2004 |

|

Headquarters |

France |

|

Sales Area |

Worldwide |

|

Business Overview |

Arkema manufactures and markets a wide range of chemicals. The Company manufactures both industrial chemicals and performance products including acrylics, polymethyl methacrylate (PMMA), hydrogen peroxide, technical polymers, specialty chemicals, and functional additives. |

We provide more professional and intelligent market reports to complement your business decisions.