Sandwich

panels for construction are composite materials used for thermal insulation.

The internal filling material (PIR, PUR, rock wool) is located between two

painted galvanized or aluminum trapezoidal panels. Sandwich panels for

construction are used as coatings for building roofs, facades and internal

partitions or cold air rooms; it provides high thermal insulation, waterproof

and sound insulation effects in the use area, and prevents moisture

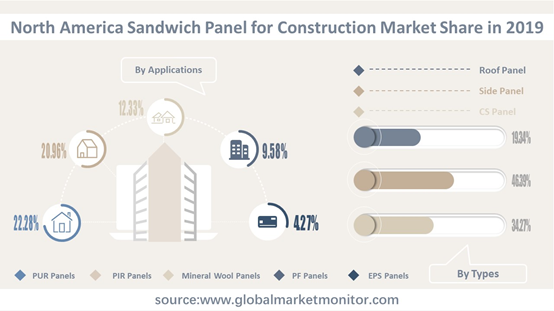

condensation. According to the type, it can be divided into PIR Panels, PUR

Panels, Mineral Wool Panels, PF Panels, EPS Panels, etc. PIR foam panels

laminated with pure embossed aluminum foil are used for fabrication of pre-insulated

duct that is used for heating, ventilation and air conditioning systems.

Prefabricated PIR sandwich panels are manufactured with corrosion-protected,

corrugated steel facings bonded to a core of PIR foam and used extensively as

roofing insulation and vertical walls. PUR insulation can be injected into wall

cavities to create an energy efficient barrier. The foam is able to reach small

spaces to create an air tight seal. PUR provides “the best thermal performance

of all practical full cavity insulants.” PUR foam can be continuously sprayed

onto any type of surface. It is generally less expensive than other materials,

making it ideal for renovations. In flood prone areas, PUR’s high water

resistance can minimize the impact of water damage in wall cavities, since it

is a material that does not hold moisture. Mineral wool is any fibrous material

formed by spinning or drawing molten mineral or rock materials such as slag and

ceramics. Mineral Wool Panel has the characteristics of incombustibility and

moisture resistance, cannot burn or release gas in fire, is stable in size,

hydrophobic and cannot expand. Suitable for commercial and industrial

applications, arenas and manufacturing facilities. PF Panels is made of

phenolic foam material. Phenolic foam is a new generation of thermal

insulation, fire prevention and sound insulation material. PF Panels are light,

fireproof, non-combustible, smoke-free, non-toxic, non-dripping, wide

in-service temperature, non-shrinking and non-embrittlement in low temperature

environment, and are widely used in buildings. Polystyrene foam panel, also

known as EPS board, is a white object made of expandable polystyrene beads

containing volatile liquid foaming agent, which is heated and molded in a mold

after pre-heating. It has the structural characteristics of fine closed pores,

and is mainly used for building walls, roof insulation, composite board

insulation, cold storage, air conditioning, vehicle and ship insulation, floor

heating, decoration carving, etc., and has a wide range of uses. Roof plate is

a plate that can bear roof load directly. Roof panel is located on the roof of

a house, and Sandwich Panel for Construction has certain bearing capacity and

can be applied to roof panel. The side panel is mainly located on the side of

the house, which needs to have a certain ability of wind and rain protection.

Sandwich Panel for Construction can be applied to the side panel. The ceiling

is the interior top surface of a building. Sandwich Panel for Construction can

be used as CS Panel, which has certain bearing capacity and can also circulate

indoor and outdoor air.

The Influence of COVID-19 on North America Sandwich Panel for Construction

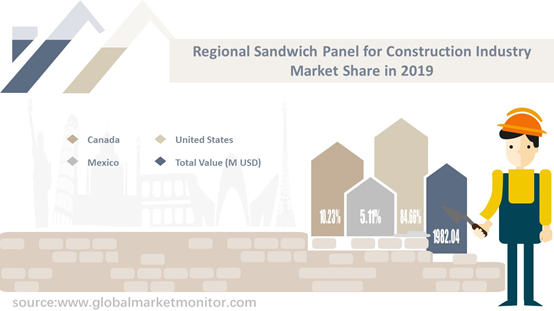

The United States was the largest revenue market with a market share of 83.27% in 2015 and 84.66% in 2019, an increase of 1.39%. In 2019, Canada market share was 10.23%, ranking second. In addition, Mexico Sandwich Panel for Construction market is expected to be the growing market. With the development of economy, increase downstream demand, progress in the construction industry will promote the Sandwich Panel for Construction market. Sandwich Panel for Construction companies are mainly from North America; the industry concentrate rate is high. The market share of the top three companies in 2019 was 65.60%. The top three companies are Kingspan Group, NCI Building Systems Inc, Nucor Corporation, with the revenue market share of 38.19%, 20.49%, 6.92% in 2019

Get Sample Copy of ${@@@@} Market Report at: https://www.globalmarketmonitor.com/reports/762440-sandwich-panel-for-construction-market-report.html

During the outbreak, people spent a lot of time indoors-about 90% of the usual time-and the lockout policy associated with the COVID-19 response only increased the amount of time indoors. It also sounded the alarm for people. Since most of the life and work are indoors, indoor air quality needs to be guaranteed. People can improve air quality by increasing the weather resistance of buildings. Weathering, including exterior housing, roofing membranes and advanced insulation, helps prevent the penetration of microorganisms, dust, pollen and mold spores that cause infections, allergies and immune system stress. Creating a healthier indoor environment not only reduces the risk of disease transmission, but also improves people\'s health and productivity. Improving the indoor environment and reducing the incidence of colds, flu and related illnesses would also bring huge economic benefits. This healthy building trend will increase demand in the Sandwich Panel for Construction industry and encourage businesses to develop innovative products. Although the 2020 new crown epidemic has slowed down the development speed of the construction splint industry in North America, it has also provided companies with new development ideas and directions in the industry.

The Forecast of Sandwich Panel for Construction Market in North America

According to our research, the Global Sandwich Panel for Construction market has a total sales value of 1632.34 M USD back in 2015, and increased to 1982.04 M USD in 2019. We made a series of functional calculation and deduced the past 5 year’s data with scientific model. Finally, we made the prediction that the sales value of Sandwich Panel for Construction markets can be 2766.17 M USD by 2025. The CAGR of Sandwich Panel for Construction is 5.71% from 2019 to 2025.

The versatility of Sandwich Panel for Construction means that these panels have many uses and various forms. In buildings and buildings, these prefabricated products are designed to be used as building envelope. They appear in industrial and office buildings, clean rooms and cold rooms, and private houses, whether renovated or newly built. Sandwich Panel for Construction combines high-quality products with highly flexible design. Sandwich Panel for Construction usually have good energy efficiency and sustainability. In the past 40 years, the construction technology of Sandwich Panel for Construction has made great progress. Previously, Sandwich Panel for Construction was considered as a product only applicable to functional buildings and industrial buildings. However, due to its good thermal insulation, versatility, quality and attractive visual appearance, panels are increasingly used in various buildings. These factors increase the demand for Sandwich Panel for Construction in the construction industry, thus driving the development of Sandwich Panel for Construction industry. Sandwich Panel for Construction cannot maintain its integrity in fire, and these panels may actually contribute to the spread of fire. Polystyrene and polyethylene cores begin to melt at a temperature of about 200 F, which makes these plastics flow like flammable liquids and catch fire. Polyurethane, polyisocyanate and FRP are ignited in the range of 650 F to 1000 f. All these materials will release thick black smoke when burning. Under proper conditions, all materials will burn whether flame retardant is used or not. Buildings of this structure are prone to collapse in fire. Panels made of glass fiber or mineral wool will not burn, but they will not be well supported in fire and easily collapse. These factors limit the development of Sandwich Panel for Construction industry.

In recent years, extreme weather events have become more frequent. The scope of damage has led architects and construction engineers to re-examine building materials in order to learn how to make elastic houses that can resist natural disasters. Steel insulation panel, referred to as SIP for short. Two steel plates sandwich four inches of foam insulation to form a lightweight panel. Since the internal frame is also made of steel, there is no waste wood and no termite hazard. The panel also has fire resistance of up to two hours, hardly produces smoke, and does not allow the fire to spread. The electricity cost of a house built with such sandwich panels is usually 50- 60% lower than that of other houses of similar size. By putting solar cells on the roof, the energy cost is actually smaller. This construction method is an ideal choice for North America because there is a large demand for affordable houses and less inventory. North American consumers are buying more houses than they can afford, and the growing population in the region is pushing up the prices of existing and newly built houses. The rapid construction time of SIP houses can help builders in North America reduce their burdens. The construction cost of these houses is usually not cheaper than that of traditional houses, but SIP houses have long-term benefits due to their high energy efficiency, strong and durable structure and low insurance premium. The application of the new Sandwich Panel for Construction will bring new development opportunities to the Sandwich Panel for Construction industry.

| Get Sample Copy of ${@@@@} Market Report at: https://www.globalmarketmonitor.com/reports/762440-sandwich-panel-for-construction-market-report.html |

We provide more professional and intelligent market reports to complement your business decisions.