One of the key components in vibration sensor testing technology, its function is mainly to receive the mechanical quantity and convert it into a proportional amount of electricity. Because it is also a kind of electromechanical conversion device, we sometimes also call it transducer, vibration picker, etc.

The vibration sensor is not directly the original mechanical quantity to be measured into electricity, but the original mechanical quantity to be measured as the input of the vibration sensor, and then by the mechanical receiving part to receive, forming another suitable for the transformation of mechanical quantity, and finally by the mechanical and electrical transformation part will be transformed into electricity. Therefore, the working performance of a sensor is determined by the working performance of the mechanical receiving part and the electromechanical transformation part.

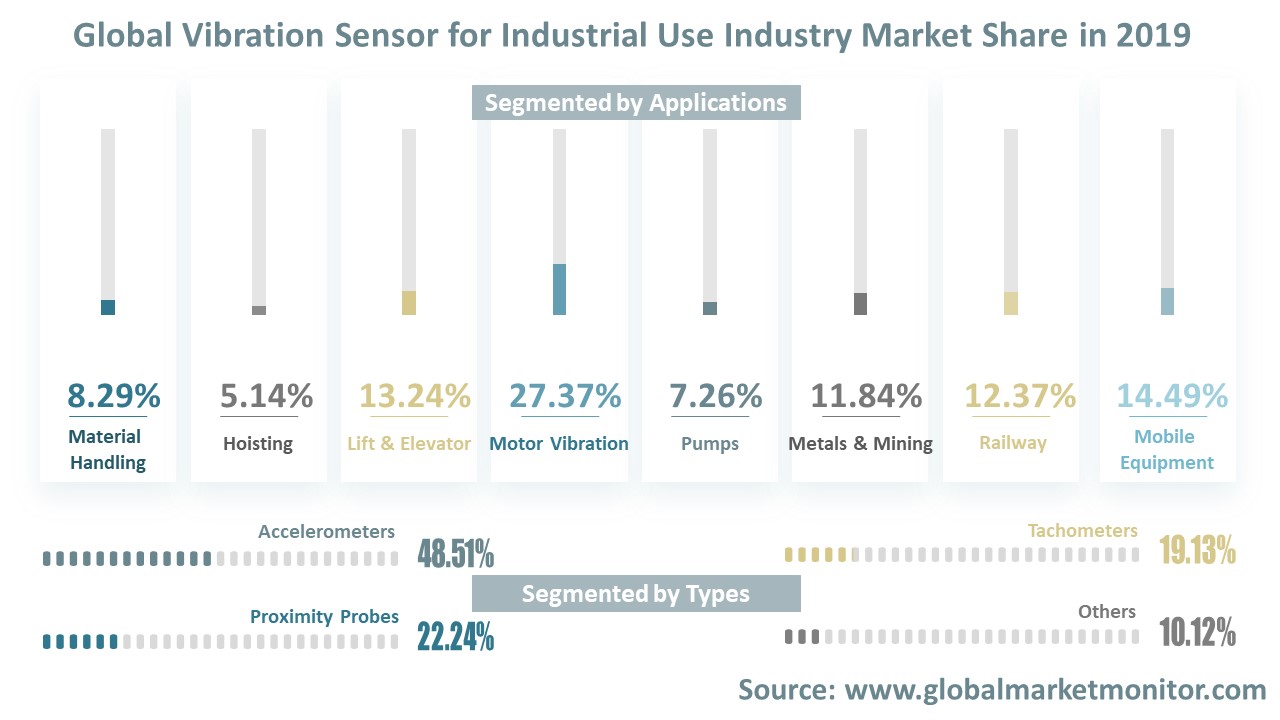

In terms of the downstream application market, industrial vibration sensors are used in various fields such as material handling, lifting, elevator, motor vibration, pumps, metal & mining, railway, and mobile equipment. Among them, motor vibration, mobile equipment, elevator and metal and mining applications accounted for a relatively high proportion, in 2019, the market value accounted for 27.37%, 14.49%, 13.24% and 11.84%.

Analysis of the global industrial vibration sensor industry market

In the highly developed modern industry, modern testing technology to the digital, information direction has become an inevitable development trend, and the front of the test system is the sensor, it is the soul of the whole test system, is listed as the world\'s cutting-edge technology, especially in recent years the rapid development of IC technology and computer technology, It provides a good and reliable scientific and technical basis for the development of sensor. So that the development of sensor day new month, and digital, multifunctional and intelligent are the important characteristics of the development of modern sensors.

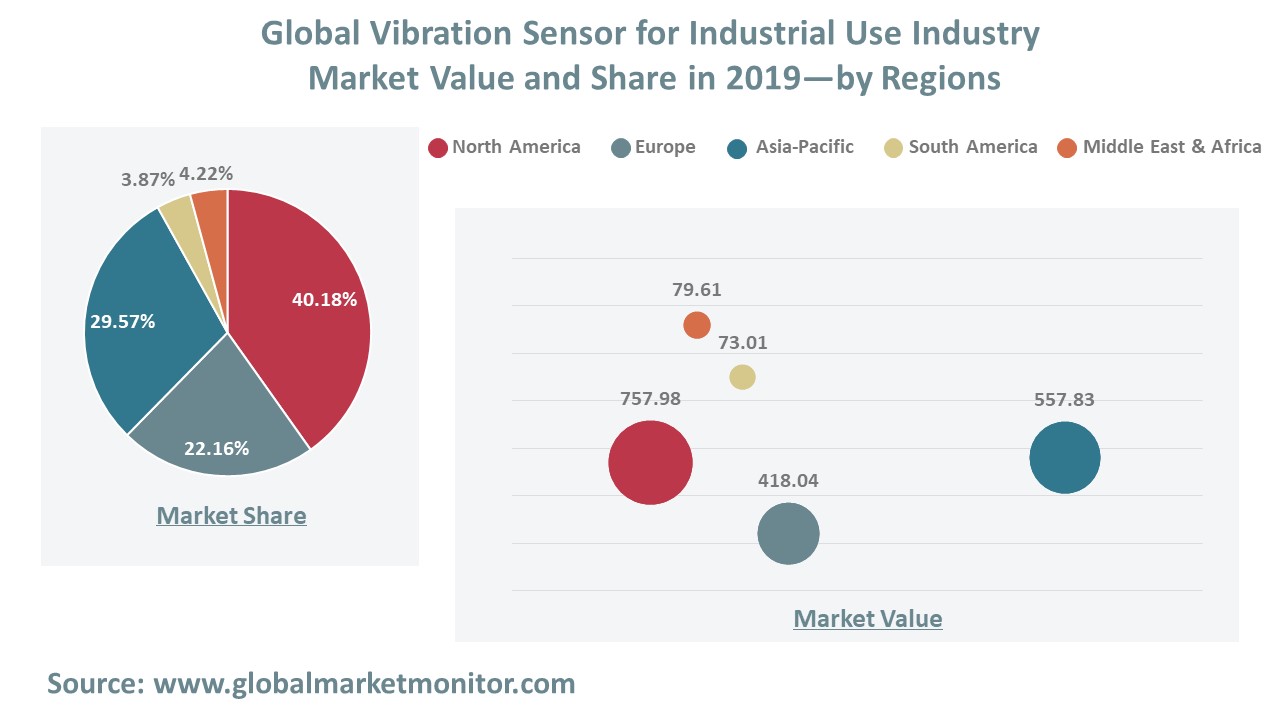

The research shows that the global industrial vibration sensor industry has a high geographical concentration, and North America is the largest market for industrial vibration sensor industry by revenue. In 2019, the North American industrial vibration sensor industry accounted for 40.18% of the global market with a market value of $757.98 million; Second, the Asia-Pacific market accounted for 29.57%, with a market value of $557.83 million in 2019; The industrial sensors market in Europe ranks third in the world with a value of $418.04 million, accounting for 22.16%; Latin America and the Middle East and Africa markets are relatively small, with market values of $79.61 million and $73.01 million in 2019, respectively, accounting for only 4.22% and 3.87% of the global market, respectively.

Get complete sample, please click: https://www.globalmarketmonitor.com/reports/1207535-vibration-sensor-market-report.html

The increasing demand for machine monitoring and maintenance continues to drive the development of vibration sensors market for industrial use

The development of modern economy is inseparable from the machinery manufacturing industry, which plays an increasingly important role in the national economy. Machinery manufacturing industry is the basic industry of the national economy. Its development directly affects the development of all sectors of the national economy, and also affects the strengthening of the national economy, people\'s livelihood and national defense construction. Therefore, most countries put the development of machinery manufacturing industry in the first place. The development of any industry in the national economy must rely on the support of the machinery manufacturing industry and the provision of equipment; In many countries, manufacturing technology accounts for more than 60% of national economic productivity. Today, the four major sciences -- manufacturing science, information science, materials science and biological science -- are interdependent; But the latter three disciplines must rely on manufacturing science to form industries and create social material wealth.

With the rapid development of science and technology, the degree of mechanical industrialization is also increasing rapidly, and the mechanical equipment of modern industrial production is gradually becoming more complex, high-speed and automated. In order to master the running state of equipment, avoid accidents and strive for longer service time, people pay more and more attention to the monitoring and fault diagnosis of key units in production. And the vibration sensor undertakes this important task. For example, when the pump room or unit vibration, the staff will according to the specific situation, the use of vibration sensor one by one measurement of the cause of vibration, to find out the crux of the problem, and then take effective technical measures to eliminate. Therefore, the increasing demand for machine monitoring and maintenance will continue to drive the development of the industry.

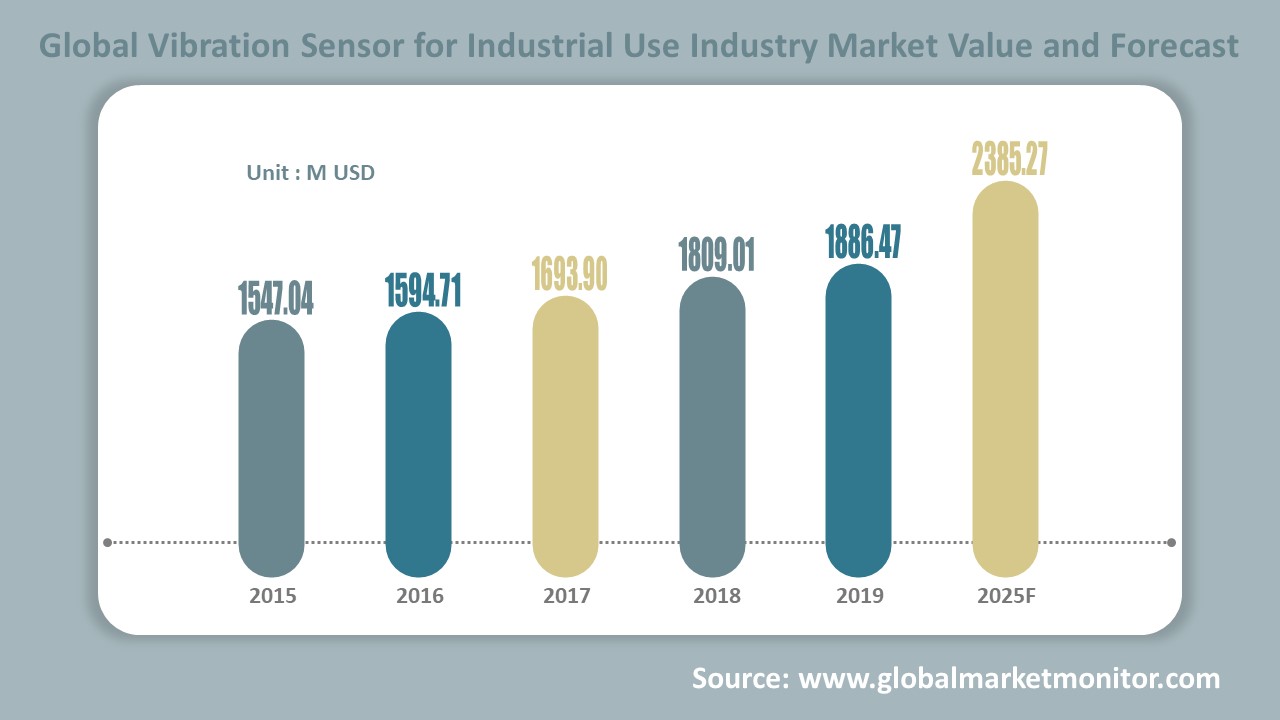

In addition, complex industrial production processes increasingly rely on the efficient, reliable and consistent operation of motors and related mechanical equipment. Mechanical and equipment imbalances, defects, loose fasteners, and other anomalies often translate into vibration, resulting in reduced accuracy and safety issues. If neglected, in addition to performance and safety issues, there will inevitably be a loss of productivity if equipment is shut down for maintenance. Even small changes in equipment performance are often difficult to predict in a timely manner and quickly translate into significant productivity losses. The growing demand for process monitoring and state-based predictive maintenance also provides an opportunity for vibration sensors to expand the market, which is expected to reach a value of $238.27 million worldwide by 2025.

Get complete sample, please click: https://www.globalmarketmonitor.com/reports/1207535-vibration-sensor-market-report.html