Global Polycarbonate Diol Market Overview

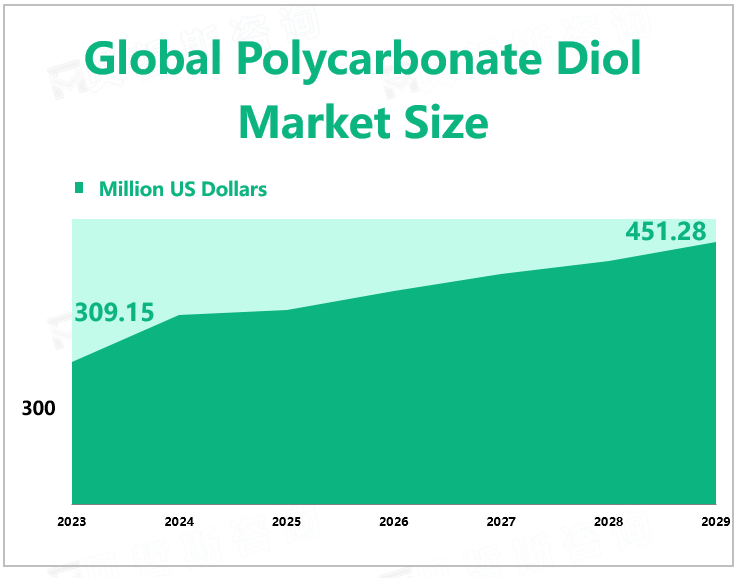

According to Global Market Monitor, the global polycarbonate diol market size will reach $309.15 million in 2024 and is expected to grow to $451.28 million by 2029.

Polycarbonate diols are premium polyester polyols. Compared to standard polyester polyols, polycarbonate diols provide significantly enhanced hydrolytic stability, impact resistance, hardness, and chemical resistance. Polycarbonate diols are commonly used in the synthesis of polyurethane resins, acrylic resins, polyester resins, and the like.

The Needs of the Leather Industry

The growth of the synthetic leather industry has been influenced by the availability of raw materials, increasing environmental concerns, protection of animals, and changing consumer demands. As a result, the world has witnessed a major shift in the market from natural leather to synthetic leather. PU synthetic leather has excellent physicochemical properties and more closely resembles natural leather in terms of treatment, texture, and appearance. Due to the performance benefits of synthetic leather, it has replaced natural leather not only in furniture, clothing, luggage, bags, and shoes but also in car seat interiors and upholstery. The demand for high-quality, functional polyurethanes from global synthetic leather manufacturers continues to grow as the production of synthetic leather products increases and the industry structure upgrades.

Increasing Environmental Awareness

Polycarbonate diols have been widely used to produce a wide range of polyurethane materials with excellent quality and performance. In addition, with increased global environmental awareness and stringent regulations, the industry's preference for polyurethane materials has shifted from solvent-based to water-based. To alleviate this problem, polycarbonate can be used instead of traditional polyols to improve the hydrolysis resistance of polyurethane materials. Therefore, polycarbonate diols can be widely used in the production of water-based polyurethane materials.

Asia Pacific led the global share of polycarbonate diols. This growth is attributed to the rapid expansion of the economy, as well as growing industries such as automobiles, construction, and consumer goods. The growing demand for innovations to improve vehicle performance, comfort, and efficiency is driving the development of polycarbonate diols systems, thus driving the market in this region.

Regulations in the plastics industry have a significant impact, driving industry players to invest in advanced technologies and quality assurance measures. Compliance with regulatory frameworks ensures patient safety, promotes innovation and builds trust among customers. Polycarbonate diol technology is more expensive to develop, manufacture, and implement than traditional plastic technology, especially for small manufacturers with limited resources. This can create potential growth for traditional alternatives to the market, mainly in underdeveloped economies.

|

Drivers |

The Development of the Global Electronic Information Industry |

|

Demand for Downstream Industry Products |

|

|

The Product Application Field is Wider. |

|

|

The Development of Emerging Countries |

|

|

Limitations |

High Technical Requirements |

|

There are Some Harmful Ingredients in the Product. |

We provide more professional and intelligent market reports to complement your business decisions.