Global High Purity Tube and FittingMarket Overview

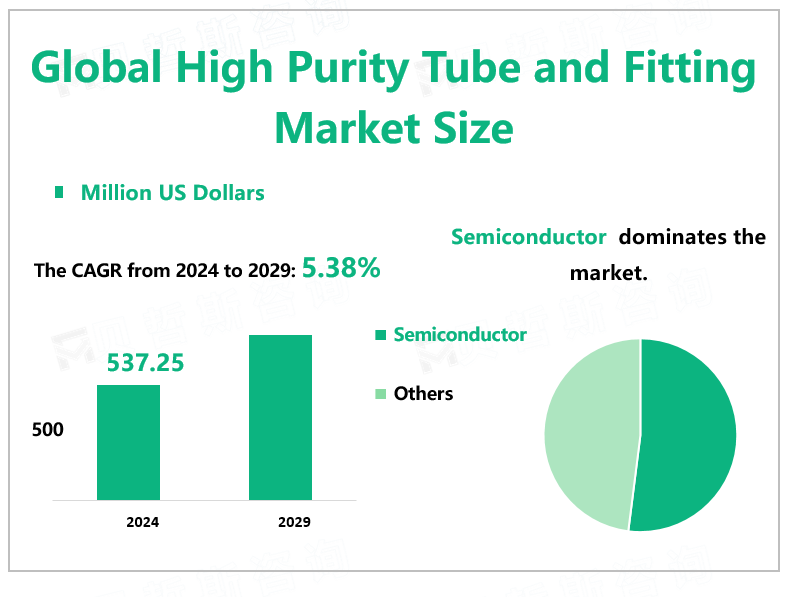

According to Global Market Monitor, the global high-purity tube and fitting market size is $537.25 million in 2024 with a CAGR of 5.38% from 2024 to 2029.

High-purity tube and fitting is widely used in various industries that require high purity, high cleanliness, and high performance, such as the semiconductor industry, pharmaceutical, laboratory engineering, high-purity gas industry, etc.

High Purity Tube and Fitting Meets the Needs of the Food and Beverage Industry.

On the one hand, High Purity Tube and Fitting ensures good hygienic conditions during the production of food and beverages. Cleanliness is a top concern for the food and beverage industry, and food and beverage manufacturers must follow strict equipment cleaning and sanitizing protocols. Pipes used in food and beverage production facilities must meet strict quality and regulatory requirements to ensure hygienic conditions. In addition to hygienic requirements, the industry often requires corrosion resistance in acidic environments. In the world, food safety has gradually become a major concern of the public, so the food and beverage industry must ensure food and beverage safety during the production process. For example, beverages such as cola, orange juice, coconut juice, etc., need to be strictly controlled during the production of these beverages. The selection of food-grade certified high-purity tubes and fittings ensures the safety of beverages. In addition, the corresponding high-purity tube and fitting need to be used in the processing of sugar, meat, fish, and other foods. High-purity tubes and fittings can meet the production needs of the food and beverage industry.

On the other hand, consumers need food-grade high-purity straws when consuming food and beverages. For example, the consumption of milk tea, milk, yogurt, and other beverages requires high-purity straws.

At present, the global food and beverage industry market is relatively large, and the demand for high-purity tubes that fit in the food and beverage industry drives the development of the industry.

The Development of Downstream Industries Drives Demand Growth.

In the pharmaceutical industry, good piping technology is an essential condition for the successful operation of any solid dosage system or biologics system unit. All systems are composed of process equipment and piping, which must be able to complete adequate sewage, thorough cleaning, and complete sterilization to meet the production needs of pharmaceutical products. Second, the pharmaceutical industry has very high requirements for ultra-high purity and corrosion resistance. Due to the harsh environment of chemical and part cleaning processes, purity tubes and fittings for pharmaceutical applications must withstand repeated aggressive chemicals and high temperatures.In the pharmaceutical industry, high-purity tubes and fitting are used in various pharmaceutical production such as fluid transfer, filling operations, and peristaltic pumping. The global pharmaceutical industry is constantly evolving, and the pharmaceutical process has increased the demand for high-purity tubes and fittings.

Semiconductors need a very clean environment during the manufacturing process, and semiconductors need to deliver ultra-pure gases. High-purity tubes and fittings meet the production needs of semiconductor products. With the development of society, the market demand for various products such as smartphones and electrical appliances has increased, and the global demand for chips is huge. In recent years, several governments have issued a series of policies to support the development of the semiconductor industry. The global semiconductor market is expected to grow with global technological progress and the industrial application of 5G technology, artificial intelligence, new energy vehicles, and other technologies, further increasing the demand for high-purity tubes and fittings.

|

Drivers |

The rapid development of the semiconductor industry |

|

Continuous innovation |

|

|

Increased competition |

|

|

Challenges |

Fluctuation in raw material prices |

|

Product quality issues |

|

|

Low rate of profitability |

We provide more professional and intelligent market reports to complement your business decisions.