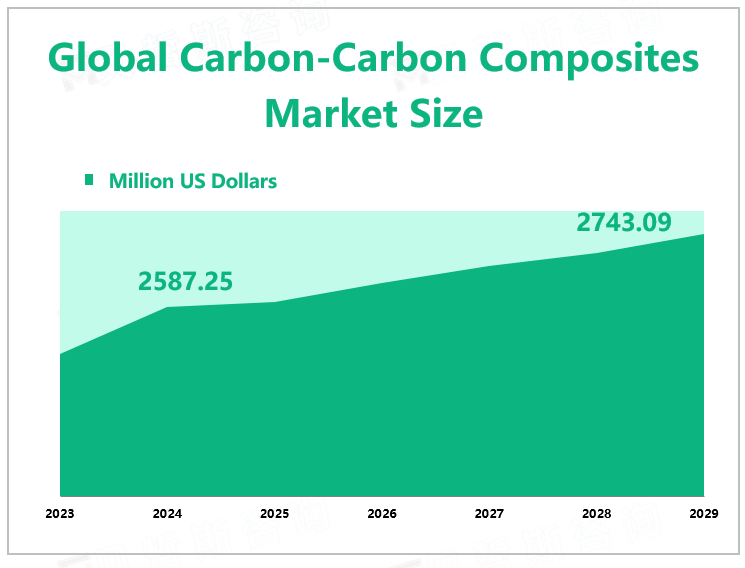

Global Carbon-Carbon Composites Market Overview

According to Global Market Monitor, the global Carbon-Carbon composites market size is $2587.25 million in 2024 and is expected to grow to $2743.09 million by 2029.

Carbon-carbon composites are composite materials composed of carbon fibers and matrix phases (such as coke, sintered carbon, and graphite) and have the characteristics of low density, high mechanical strength, high thermos ability, high electrical conductivity, high thermal conductivity, low CTE, excellent fracture toughness and high friction/wear resistance. It can be used in defense, aerospace, automotive, and other fields.

Regional Market

The United States attaches great importance to the development of the aerospace field. Whether it is from aerospace legislation or policy support, it vigorously supports aerospace development. The development of the aerospace field in the United States is a typical example of "military-civilian integration". Through public-private cooperation, NASA has invested capital and technology in space companies to foster the rapid rise of commercial lunar exploration forces. At the same time, space companies have also provided effective support for government-led lunar exploration activities. On the one hand, the development of military-civilian integration has eased the pressure on the US defense economy, and on the other hand, it has also promoted the progress of aerospace technology and the development of the national economy. Therefore, the strong strength of the United States in the aerospace sector has made the country a key area for the Carbon Carbon Composites market.

SpaceX revealed that its 2024 goal is to conduct 144 launches, which would be a 47% increase from 2023, meaning that SpaceX will complete an average of one rocket launch every two and a half days this year. In 2023, in addition to the two "Starship" test flights, SpaceX completed a total of 96 rocket launches, and all were successfully placed in orbit. Although it did not reach the goal of 100 launches set at the beginning of the year, this did not prevent SpaceX from setting a new world record.

China has been vigorously developing the aerospace field. In recent years, drawing on the commercial rocket model of the United States, Chinese private rocket companies have begun to emerge. Therefore, the vigorous development of the aerospace field has prompted the China region to become the focus area of the Carbon-Carbon Composites market. In addition, the photovoltaic field is also one of the key downstream fields of Carbon-Carbon Composites products. With the introduction of China's "carbon peak" and "carbon neutral" policies, the application demand for Carbon-Carbon Composites in photovoltaic thermal field components is likely to grow at a high rate, and in the future, "carbon-carbon composites will be the sales revenue of downstream applications." There may be exponential growth. Compared with the carrying capacity of SpaceX, the carrying capacity of China's active carrier rockets is still low, and it is in urgent need of breakthroughs in medium and large reusable liquid launch vehicle technology.

Market Segmentation

According to the different production processes of Carbon-Carbon Composites products, Carbon Carbon Composites products are divided into Chemical Vapor Deposition, Liquid Impregnation Process, and Others. The Chemical Vapor Deposition segment contributes the largest market share. The Chemical Vapor Deposition method utilizes the carbon produced by the pyrolysis of hydrocarbons such as methane and propylene at high temperatures to deposit in the pores of the carbon fiber preform to achieve densification of the carbon fiber preform, thereby obtaining a carbon/carbon composite material.

The matrix phase of carbon-carbon composite is carbon, and the reinforcement body is carbon fiber. It replaces the high-melting metals, pyrolytic graphite, polycrystalline graphite, and ablation-resistant plastic composites that were used primarily in the ablative components of early rockets. At present, the throat linings of anti-ablative parts of rocket engines in the aerospace field are all made of carbon-carbon composite materials, which have great potential in the aerospace field.

|

By Type |

Chemical Vapor Deposition |

|

Liquid Impregnation Process |

|

|

Others |

|

|

The Chemical Vapor Deposition segment contributes the largest share. |

|

|

By Application |

CZ and DSS Furnaces |

|

C/C Grid Shelving Systems |

|

|

Glass Handling Industry |

|

|

Aerospace Items |

|

|

Others |

|

|

The Aerospace Items segment occupies the biggest share. |

We provide more professional and intelligent market reports to complement your business decisions.