Global Aluminum Composite Panel (ACP) Market Overview

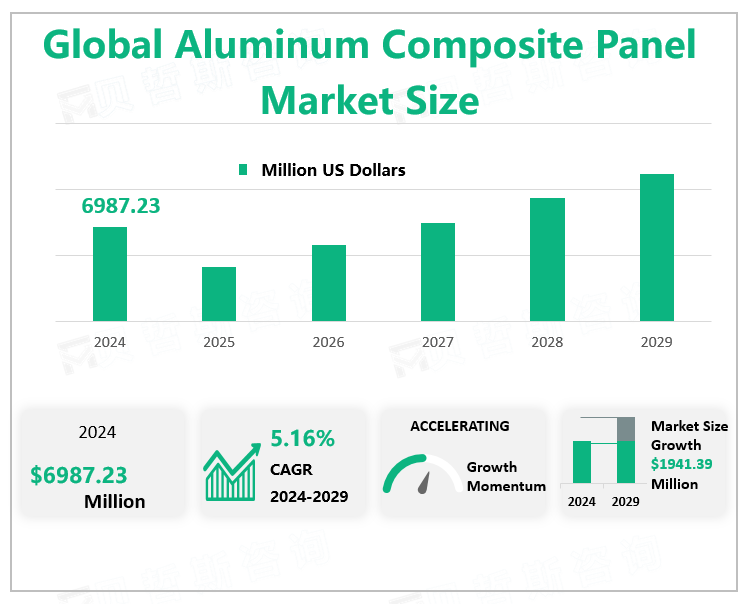

According to Global Market Monitor, the global aluminum composite panel market size will be $6987.23 million in 2024 with a CAGR of 5.16% from 2024 to 2029.

An aluminum composite panel, generally known as an ACP, is a flat panel product made up of two aluminum sheets with a non-aluminum core. The core is made of polyethylene or a mix of polyethylene and fire-resistant mineral filler.The aluminum composite panel is produced by a continuous lamination process, in which a sheet of the material that will make up the core is extruded and compacted between two aluminum sheets that are unwound at the same time. Finally, the flatness of the material is compacted and perfected and a protective film is applied.

Aluminum composite panels are new-age materials that are used for building front elevation (facades), interiors, signage, modular kitchens, and many more. It is available in a wide range of colors and textures.

Market Competition

The aluminum-plastic panel industry has a certain scale of enterprises, in the production technology and product quality has a certain guarantee, but the overall quality of the industry is still uneven. In developing countries and regions, the aluminum-plastic panel industry has a characteristic, the number of aluminum-plastic panel plants is relatively large, and the scale is generally small. The blind construction of aluminum-plastic composite panel production lines is due to market potential and profit margins, leading some enterprises to produce low-grade products in the case of imperfect technology, research and development, production management, and product inspection.

Product manufacturing process innovation

The non-aluminum core of the original ACP is highly flammable and made of polyethylene, which is a thermoplastic polymer with highly flammable properties. Since the initial combustible design, aluminum composite panels have developed a lot. The main difference lies in the core. The material that makes up the core and how it is laminated to aluminum are the key characteristics that define whether the material is flammable or not. Many manufacturers have added inorganic mineral fillers into ACP cores to reduce the flammability of products and reached the standard of A1-grade fireproof materials. The A2-grade ACP products are filled with incombustible inorganic substances as core materials, which makes them have greater resistance in case of fire or special ductility. In addition, the types of product finishes are also constantly improving, and aluminum composite panels allow a large number of different finishes, such as texture effects, matte or high-gloss surfaces, and so on. The progress of manufacturing technology and ACP products have the characteristics of high dimensional stability, recyclability, quick and simple assembly, etc. Constantly improving product performance promotes the continuous improvement of industry demand.

Consumers are increasingly inclined to diversify their consumption channels. With the rapid development of the Internet age, sales forms are constantly innovating, and the online marketing of aluminum composite panels shows great advantages in the fierce market competition. Compared with traditional marketing channels, the advantages of online sales are improved sales cost, channel management cost, information flow, and capital flow. The new online sales channel not only simplifies the composition of various channels in traditional marketing but also integrates sales, pre-sales, and after-sales service, commodity, and customer information inquiry, which has great advantages. The further development of online sales of aluminum composite panels will further promote the sales volume of the whole market.

|

Drivers |

Product manufacturing process innovation |

|

Online sales channels have developed rapidly. |

|

|

Constraints |

Product quality problems |

|

Affected by fluctuations in raw material prices |

We provide more professional and intelligent market reports to complement your business decisions.