Calcium

carbide is an inorganic compound with a molecular formula of CaC2. When pure,

it is transparent and colorless. It is also an important basic chemical raw

material, and it will react violently to generate acetylene and exothermic when

it meets with water. Industrial grade calcium carbide is a gray-black

agglomerate produced from a mixture of lime and coke in an electric arc furnace

at about 2,200°C. The cross-section is purple or gray, and its purity is about

80%. The laboratory uses pure calcium cyanamide to prepare pure white calcium

carbide by thermal decomposition in a vacuum and carbon environment.

Calcium

carbide is not only an excellent PVC material, but also a high-efficiency

desulfurizing agent. Its desulfurization capacity and desulfurization speed are

higher than those of lime and soda ash systems. In the production of steel and

ductile iron, calcium carbide is suitable for the rapid treatment of a large

amount of molten iron to obtain pig iron with extremely low sulfur content.

Calcium carbide is a strong reducing agent that can react strongly with

oxidizing substances, reducing all metal oxides to pure metals or turning them

into carbides. For example, calcium carbide can directly reduce copper sulfide

to metallic copper. In addition, the reaction of calcium carbide with water can

release acetylene gas, so it can also be used as a dehydrating agent.

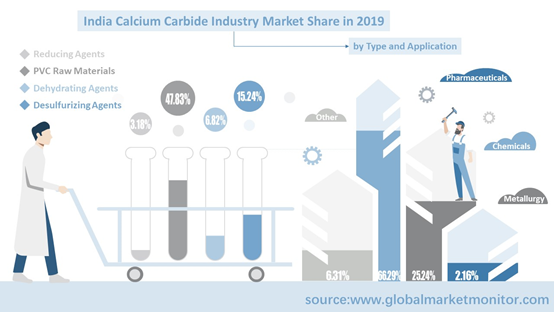

Calcium carbide and its by-products are basic chemical products widely used in chemical, pharmaceutical, metallurgical and other industries. It can be directly used as a raw material for chemical processing to react with water to generate acetylene and calcium hydroxide to achieve its main purpose and maximum utilization. The unique chemical properties of triple-bonded carbon atoms in acetylene molecules make various useful chemical reactions generate intermediates, which can be used to make various chemical derivatives. Calcium carbide can be used as a dehydrating agent and a reducing agent in the metallurgical process, as well as a necessary tool to remove unnecessary iron oxide from the slag entering the ladle during the tapping process. In addition, calcium carbide acetylene reacts with formaldehyde to generate butynediol, which is then hydrogenated to generate BDO, which can be used as a solvent in the pharmaceutical industry.

Analysis on the Current Situation of India Calcium Carbide Industry Under the Influence of COVID-19 Epidemic

India includes 28 states, six federal territories and one national capital jurisdiction. Among them, Rajasthan was the largest revenue market with a market share of 52.80% in 2015 and 51.31% in 2020 with a decrease of 1.49%. Maharashtra ranked the second market with the market share of 6.56% in 2019. Also, the Chhattisgarh and Maharashtra markets for calcium carbide are expected to be the market with the most promising growth rate.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/762974-calcium-carbide-market-report.html

Therefore, calcium carbide companies are mainly from Rajasthan with very high industry concentrate rate. The top two companies are DCM Shriram Consolidated Ltd. And ALMAMET with the market share of 50.74% and 11.06% in 2019.

Chemical industry is a knowledge- and capital-intensive industry, a pillar industry for the development of industry and agriculture, and the foundation of downstream industries. At this stage, due to a prominent structural advantage in the chemical industry, India has become a net importer of chemical products with a huge domestic market.

Nevertheless, China has become the largest calcium carbide producer and consumer, and the largest calcium carbide exporter in the word for the low production cost and high product quality. 88% of India calcium carbide imports came from China from 2018 to 2019, which shows that India import demand for calcium carbide is still continuing.

In the first quarter of 2020, the calcium carbide industry was hit by COVID-19 epidemic, the production load of the entire industry has dropped repeatedly, so market sales have dropped sharply. COVID-19 epidemic has caused a shortage of manufacturing parts, labor interruptions, and traffic interruptions, and its output may shrink significantly. At the same time, the global spread of the epidemic will also affect the import and export trade of calcium carbide. As a major importer of calcium carbide, India substantial reduction in its import trade may have a huge impact on Indian calcium carbide downstream product companies. However, the 2020 epidemic will accelerate the survival of the fittest in the calcium carbide industry and indirectly promote the transformation and upgrading of the calcium carbide industry chain.

India Calcium Carbide Industry Tends to Moderate Growth

With the growth of the market and purchasing power, the growth of disposable income and the intensification of urbanization, the demand for final consumption continues to rise, which brings huge growth opportunities for chemical companies. Therefore, India chemical industry has great potential for development, and it is expected that this market will drive the development of calcium carbide industry.

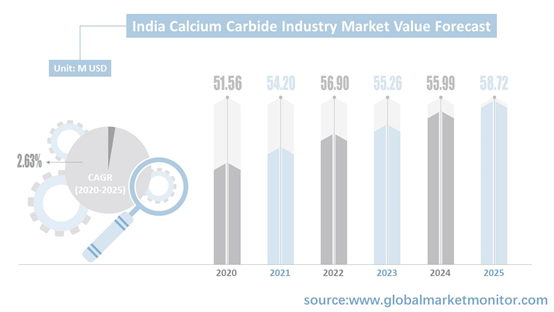

According to our research, the India calcium carbide market has a total sales value of 68.87 M USD back in 2015, and decreased to 51.56 M USD in 2020. Due to the huge market potential and wide range of applications, the Indian calcium carbide market is expected to experience moderate growth during the forecast period. We made the prediction that the value of calcium carbide markets can be 58.72 M USD by 2025. The CAGR of calcium carbide is 2.63% from 2020 to 2025.

Affected

by the epidemic, coupled with further tightening of carbon neutral

environmental protection and safety policies, and multiple uncertain factors

superimposed, the calcium carbide industry will face severe tests and

challenges.

Most of

the calcium carbide production in India is used for the production of PVC, so

the fluctuations in the downstream PVC market have a great impact on calcium

carbide manufacturers. However, the high power consumption and high pollution

of calcium carbide method PVC will be restrictive factors for the calcium

carbide method PVC production enterprises. Therefore, cost factors and

government policies have made ethylene a powerful substitute for calcium

carbide, restricting the development of calcium carbide enterprises. In

addition, for local Indian companies, Chinese calcium carbide manufacturers are

strong competitors, limiting the development of the Indian calcium carbide

industry.

But after

the epidemic, the labor-intensive and traditional management operations of the

Industrial Internet will promote the application of 5G, big data, cloud

computing, blockchain, artificial intelligence and other technologies in the

manufacturing industry, especially the medical industry. With the application

of the health industry, smart manufacturing will also usher in development

opportunities.

We provide more professional and intelligent market reports to complement your business decisions.