The melt

blown method is a method that relies on high-temperature, high-speed airflow to

blow the polymer melt to make it quickly stretched to prepare fibers. Spinneret

plate, melt blown fabric spinneret structure and the melt blown die head are

the core components of the melt blown equipment.

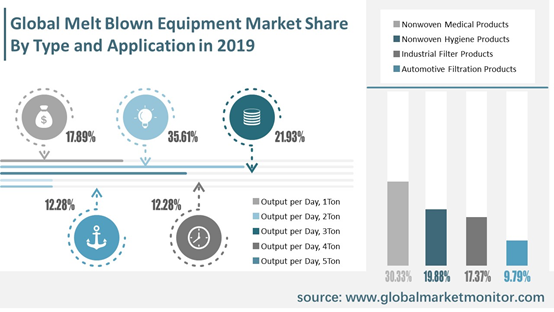

Melt blown

equipment can be divided into five types according to the maximum amount of

melt blown fabric produced per day: output per day, 1 ton, output per day, 2tons,

output per day, 3 tons, output per day, 4 tons, output per day, 5 tons. Due to

the small output of equipment with a daily output of 1 ton, which does not meet

the manufacturer requirements, the market share in 2019 is only 17.89%.

Equipment with a daily output of 2 tons and a daily output of 3 tons are the

most common and the two most popular on the market, accounting for 35.61% and

21.93% of the market respectively in 2019. The daily output of 4 tons and the

daily output of 5 tons have higher energy consumption, and both account for

12.28% of the market.

The industry application areas are medical non-woven fabrics, sanitary non-woven fabrics, industrial and automotive filter materials and other major fields. Non-woven medical supplies produced by melt blown equipment can be used as protective agents for alcohol, grease, blood, etc., applied to surgical drapes, surgical gowns and other products, and are ideal fabrics for the medical industry. Melt blown fabric has the characteristics of high strength, soft hand feeling and easy post-processing. It is an ideal material for non-woven sanitary products. It is also commonly used in feminine sanitary napkins, diaper top sheets and disposable adult incontinence products. In addition, melt blown equipment can be used to produce industrial filtration products, including surgical masks, liquid filtration, gas filtration, cartridge filters, clean room filters, etc. It can also be used to produce automotive filter products, used as a filter medium in micro-folded filters, ventilation filters and other automotive air filters, with high filtration rate and durability, lower resistance, good antibacterial properties, and improved comfort and reliability of passengers.

Melt blown fabric is an essential material for making masks, which popularity has been continued to rise in 2020. The production pressure of melt blown fabric is increasing day by day, and manufacturer demand for melt blown equipment is expanding.

Analysis of Melt blown Equipment Industry in Various Regions

The Asia-Pacific region is the largest revenue market in the melt blown equipment industry, with a market share of 44.12% in 2015 and 47.90% in 2020. The European and North American markets rank second and third with a market share of 24.51% and 21.17% in 2020.

Get the Complete Sample, Please Click: https://www.globalmarketmonitor.com/reports/763159-melt-blown-equipment-market-report.html

In Asia-Pacific region, and in the past few decades, a high degree of industrialization and the lack of strict pollution control has led to serious environmental pollution and poor air quality. Many people rely on masks when they go out every day. In addition, the large population here provides a huge consumer base for the downstream demand of melt blown equipment, so there is a large demand for melt blown equipment. In 2020, Asia-Pacific was the first place where the epidemic occur, and due to the large population base in this region, many people have been affected, thus the demand for masks will also be greater. Many manufacturers regard the Asia-Pacific region as the most developing region for melt blown equipment.

The largest company in the melt blown equipment industry is Oerlikon in Switzerland. In 2020, the operating income of it totaled 124.98 million U.S. dollars, accounting for 23.43% of the world total. Reifenhauser Reicofil and Zhejiang CL Nonwoven Machinery ranked second and third with revenues of US$103.64 million and US$23.39 million, and market shares of 19.43% and 4.38%. It can be seen that the leading companies in this industry have strong competitiveness and high market concentration.

Covid-19 Epidemic Has Had a Huge Impact on the Melt Blown Equipment Industry, and the Demand is Expected to be Small in the Next Few Years After the Epidemic

Melt blown equipment can manufacture a variety of non-woven products with a wide range of uses. With characteristics of air permeability, liquid permeability resistance, lint-free structure, impermeability to bacteria and sterilization, it is widely used in the production of personal care and sanitary products. Its development is expected to promote the market in the medical and health field. In addition, the demand for melt blown equipment in various terminal industries such as automobiles, construction, and agriculture is also increasing, which has greatly promoted the development of the melt blown equipment market.

The melt blown fabric produced by melt blown equipment is the filter layer in the middle of medical masks. It is known as the heart of masks and is one of the important raw materials for the production of medical masks, with good filtration performance, barrier performance, heat insulation performance and adsorption performance. Due to the global outbreak of covid-19 in 2020, the demand for masks has increased sharply. Facing the shortage of medical prevention and control materials such as medical masks and protective clothing, various countries have promoted the production and supply of melt blown equipment. On the basis of the original continuous growth, the global capacity utilization rate and the demand for melt blown equipment have increased significantly, which market scale has greatly increased.

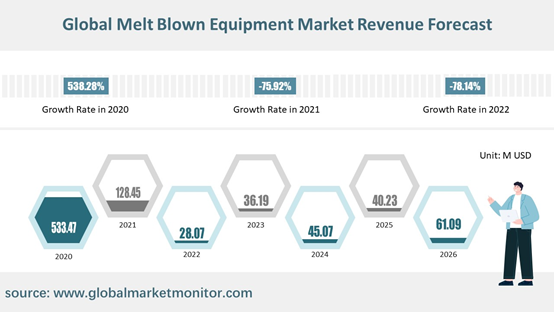

In 2015,

the global melt blown equipment industry market revenue was US$93.51 million,

and in 2020, driven by the epidemic, it increased sharply to US$533.47 million.

With the gradual recovery of the epidemic, demand tends to be saturated, but

suppliers have overcapacity problems. Therefore, the melt blown equipment industry

revenue declined rapidly in 2020. Since then, due to lower demand, overall

income has been lower than that before the epidemic, and it will be stabilized

and increased moderately thereafter. The industry market revenue is expected to

reach 61.09 million U.S. dollars in 2026.

With the

development of economy, people have put forward higher and higher requirements

for the functionality, comfort and convenience of masks. The application of

melt blown fabric with specific properties in related fields is becoming more

and more extensive. The technical upgrade and performance improvement of melt

blown equipment in the future will still be the main trend, bringing many

opportunities to the market.

We provide more professional and intelligent market reports to complement your business decisions.