Industrial automation helps improve product quality, reliability and productivity, while reducing production and design costs, by adopting new, innovative and integrated technologies and services. These devices and technologies can realize the automatic operation and control of industrial processes without manual intervention and have higher performance than manual control.

Industrial Automation Key Technologies: VR and 5G

VR can provide a highly realistic virtual training environment that contains context-sensitive real-time data. This enables operators, maintenance technicians, and plant engineers to explore a variety of plant and field conditions in a secure offline environment and to prepare for the unknown and reduced reality of the environment. VR can create training programs almost indefinitely, with zero risks of operational disruption. VR training methods are increasingly popular in process industries, where competence requires familiarity with equipment and operating and maintenance procedures. Millennials often have a hard time challenging that familiarity, especially for complex and/or rarely performed tasks. VR provides these workers with a repeatable, lowstress learning environment that enables them to master these skills

5G technology is expanding and evolving every day, bringing the next generation of mobile Internet connectivity to the world and providing faster, more reliable connections at an average download speed of 1Gbps or more. With satellite infrastructure, the Internet of things connections can also reach remote areas where mobile phone networks cannot reach. The cluster of microsatellites orbits the earth, picking up signals from tiny ground transmitters and relaying data to a ground antenna.

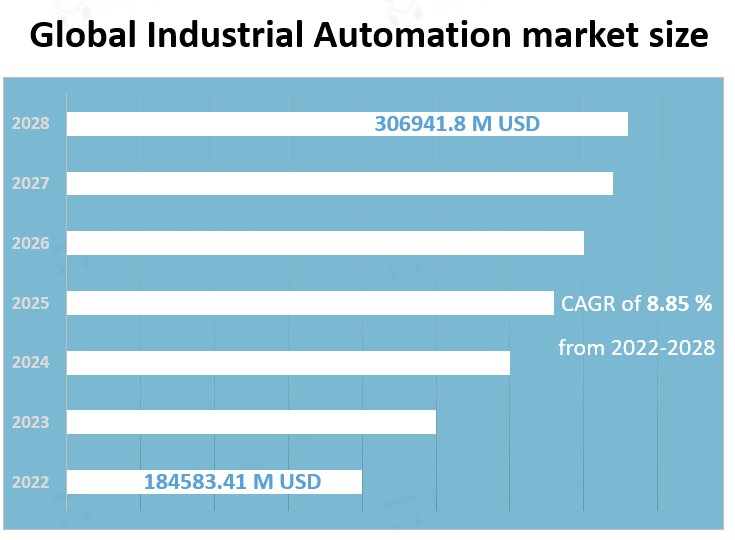

Global Industrial Automation market size was around 184.58 billion USD in 2022, and will be 306.94 billion USD. CAGR of 8.85% from 2022-2028.

Opportunities

Although with the development of industrial automation, the risk of many jobs will be replaced by automation, is a big threat for the Labor market. However, the development of technology is the inevitable trend, therefore, in the future, whether business or government, skills training for the staff will be constantly upgrade, to adapt to the new job opportunities, to bring greater economic benefits for the enterprise.

Limitations

Industrial automation is emerging in European and American countries. They also took the lead in entering Industry 4.0. They have rich experience in the commissioning, installation, and maintenance of industrial automation equipment. At the same time, the high costs and high maintenance costs involved in the R & D and installation of mechanical production systems. In developing countries, a lack of awareness of the benefits of industrial automation and skilled technical support may hinder market growth.

|

Drivers |

Industrial automation solutions of high performance and large downstream applications is one of the important factors that drive the market development. |

|

Limitations |

In developing countries, a lack of awareness of the benefits of industrial automation and skilled technical support may hinder market growth. |

|

Opportunities |

In the future, whether business or government, skills training for the staff will be constantly upgrade, to adapt to the new job opportunities, to bring greater economic benefits for the enterprise. |

We provide more professional and intelligent market reports to complement your business decisions.