DBC (Direct Bond Copper) ceramic substrate is a widely used substrate material in electronic devices. DBC process is a commonly used ceramic substrate manufacturing process, which involves adding oxygen elements between copper and ceramics, obtaining a Cu-O eutectic solution at temperatures between 1065 and 1083℃, followed by a reaction to obtain intermediate phases (CuA102 or CuA12 O), thereby achieving chemical metallurgical bonding between Cu plates and ceramic substrates. Finally, graphic preparation is achieved through photolithography technology to form circuits.

Due to the excellent conductivity and thermal conductivity of copper foil, while alumina can effectively control the expansion of Cu Al2 O: - Cu composite, the DBC ceramic substrate has a thermal expansion coefficient similar to that of alumina. Therefore, the DBC ceramic substrate has the advantages of good thermal conductivity, strong insulation, and high reliability.

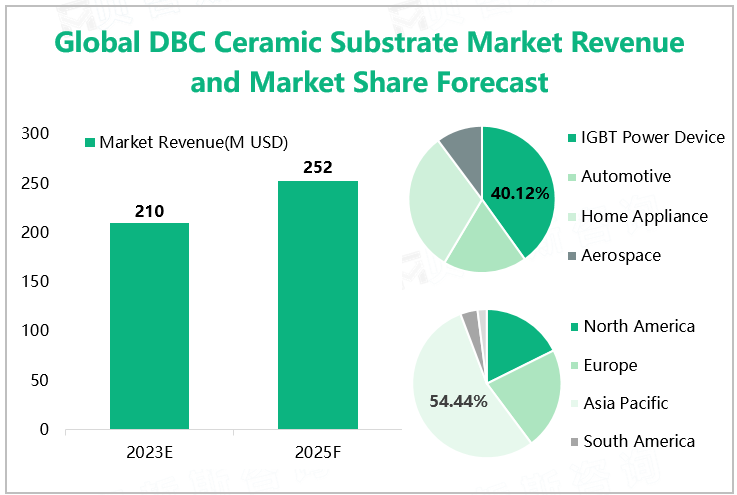

According to our research data, the global DBC ceramic substrate market revenue is expected to reach $210 million in 2023. In the future, with the continuous progress of technology and the growth of demand for electronic devices, the DBC ceramic substrate market will continue to steadily grow, and it is estimated that its market revenue will reach $252 million by 2025.

Global DBC Ceramic Substrate Market Revenue and Market Share Forecast

Source: www.globalmarketmonitor.com

From the perspective of downstream application patterns, the IGBT power device field is the largest downstream application market for DBC ceramic substrates, with an expected market share of 40.12% in 2023. In addition, DBC ceramic substrates are also widely used in fields such as automotive, household appliances, and aerospace.

In terms of regional development, research shows that the Asia-Pacific region is the largest revenue market for the global DBC ceramic substrate industry, with a market sales share expected to reach 54.44% in 2023; It is estimated that the European and North American markets will rank second and third with market shares of 22.06% and 17.60%, respectively.

From the perspective of market competition patterns, the concentration of the global DBC ceramic substrate market is relatively high. Data shows that the total revenue of the top 3 enterprises in the industry was $81 million in 2020, accounting for 57.86% of the market. The total revenue of the top 6 enterprises was $171 million, with a total market share of 83.57%. The top three companies in the rankings were Rogers, Tong Hsing, and NGK Electronics Devices. In 2020, the three companies accounted for 27.86%, 17.86%, and 12.14% of the global market revenue in the DBC ceramic substrate market, respectively.

Global DBC Ceramic Substrate Market Revenue and Share by Enterprise in 2020

|

Enterprises

|

Market Revenue(M USD)

|

Market Share

|

|

Rogers

|

39

|

27.86%

|

|

Tong Hsing

|

25

|

17.86%

|

|

NGK Electronics Devices

|

17

|

12.14%

|

|

Top3

|

81

|

57.86%

|

|

Top6

|

117

|

83.57%

|

Source: www.globalmarketmonitor.com

In the future, with the continuous development of

technology, the development of DBC ceramic substrates will present the

following trends:

Green and environmental protection: Environmental protection has become a global focus and DBC ceramic

substrates will pay more attention to environmental protection and sustainable

development in the future, such as using more environmentally friendly

materials to prepare DBC ceramic substrates, or developing low-cost and

high-yield production processes to reduce environmental impacts.

Personalized demand: As consumers\'

personalized demand for electronic devices continues to increase, the requirements

for the appearance, size, thickness, and other parameters of DBC ceramic

substrates will also become more diverse. Therefore, DBC ceramic substrates

will pay more attention to the personalized design of products in the future.

Intelligent manufacturing: Intelligent

manufacturing can improve production efficiency, reduce costs, and improve

product quality. In the future, DBC ceramic substrates will pay more attention

to intelligent manufacturing, adopting advanced automated production lines and

intelligent manufacturing technology to improve production efficiency and

product quality.

For more information, please click: 《2023 Global DBC Ceramic Substrate Market Analysis Report, Key Competitors, Market Effect Factors, Growth, And Forecast.